By Paul Moran

Purpose

This article outlines the Chrysler Lean Burn "conversion" to the earlier electronic ignition, or better stated as Lean Burn system removal from Mopar Slant Six engines (170 , 198 , 225).

This article is also useful when converting from points to Mopar's factory style electronic ignition (EI) or orange box (ECU). Conversion to the Mopar EI system paves ground for the "Super Six" swap on newer model cars and trucks which may require Lean Burn removal.

Mopar discontinued the Slant 6 EI kit for the points to electronic ignition conversion, but they still offer the V-8 version of the Kit. The V-8 version would be a solution, but the distributor is not the correct size for a Slant 6. If you have money to burn, purchase the V-8 kit (about $150), sell the V-8 distributor and buy a standard electronic distributor for a Slant Six. Any 1975-1980 model Slant Six car (and possibly many other years) would have this distributor.

What you won't learn

This

article is only the tip of the iceberg, especially if you are not

familiar with basic engine systems and maintenance. This should not

be the first or last document you read before you do this project,

but definitely read this article completely before you start. If your

engine is badly worn or damaged or in need of other maintenance, I

suggest you perform those tasks before doing this conversion. There

are some good articles at www.Slantsix.org

if you are doing the Super Six conversion. You will need to

understand how to properly set the timing on your engine and I

suggest you get familiar with the ignition timing adjustment process

before you pull the distributor. This article will not explain timing

advance curves or the mechanical and vacuum advance adjustments but

you'll want to learn how to make those adjustments to get the most

from your new ignition system. You'll also need to find information

on tuning the carburetor you decide to install along with your new EI

system.

Some background info and parts identification

Reluctor: an internal part of non-points distributors. The 6 high spots create a signal as they pass a pickup coil. The signal is then amplified by the ignition box (Mopar ECU or aftermarket units) to activate the ignition coil.

Pickup

Coil: an internal part of non-points distributors. As the peaks

of the reluctor pass the pickup coil, a small magnetic current is

created. The pickup coil is fixed in a Lean Burn distributor but

attached to the vacuum advanced pod in standard electronic

distributors.

The Lean Burn distributor looks similar to other Slant Six distributors. It uses the same 6 point reluctor as the other electronic distributors but it does not have any mechanical advance mechanism. It does not have a vacuum pot and may have 2 plugs with 2 wires each (separate start and run pick-ups for Lean Burn). All the advance is controlled by the Lean Burn computer and based on O2 sensor readings, engine temp, and vacuum signals.

Points distributor: Old style ignition system (pre 1972). Uses 1 wire and has a 6 lobed cam plate on the shaft. Contact points are a simple switch which allows 12v current flow at each low point of the lobes (points closed). This completes the circuit to the coil and sets up a magnetic field. When the points ride up on a lobe and open, current flow thru the coil stops and the magnetic field collapses through its wire windings. This action produces a high voltage spark at that moment.

Points are difficult to keep adjusted due to the rubbing action on the cam lobes and the resulting wear. Point distributors have mechanical advance consisting of weights and springs and a vacuum pot which allows for additional timing advance, controlled by carburetor "ported" vacuum.

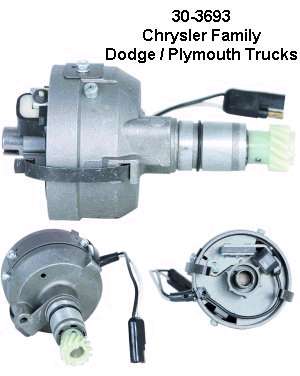

Standard Electronic Distributor: Provides precise timing with a 6 point reluctor and low voltage electronic pickup. Connects to the ECU box with a 2 wire connector. Has vacuum advance.

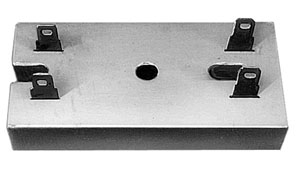

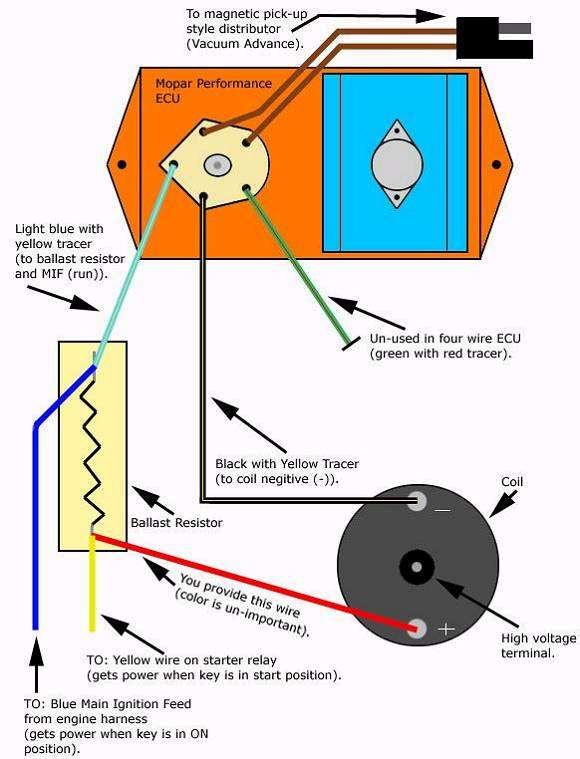

Chrysler

Electronic Ignition ECU (Electronic Control Unit) "Orange Box ":

Solid state electrical device that amplifies the low voltage signal

from the electronic distributor pickup and completes the 12v circuit

from the coil. This produces spark at the correct moment

but without the wear associated with points. This unit was essentially

the same for all Mopar factory EI engines, Slant Six or V-8, but 4

wire or 5 wire versions can be found. Either ECU can be used, but the

simpler 4 wire system is detailed here. A 5 wire ECU requires a

dual

ballast resistor and wiring

to match, but a 4 wire ECU can run on a 4 or 5 wire system without

modification to the wiring. An external ballast resistor is required

when using stock Mopar ignition coils. A .5 ohm resistor is standard

for a 4 wire EI system. A dual system has a .5 ohm resistor and a 5

ohm resistor as pictured and a points system has a special resistor

that varies with temperature.

without the wear associated with points. This unit was essentially

the same for all Mopar factory EI engines, Slant Six or V-8, but 4

wire or 5 wire versions can be found. Either ECU can be used, but the

simpler 4 wire system is detailed here. A 5 wire ECU requires a

dual

ballast resistor and wiring

to match, but a 4 wire ECU can run on a 4 or 5 wire system without

modification to the wiring. An external ballast resistor is required

when using stock Mopar ignition coils. A .5 ohm resistor is standard

for a 4 wire EI system. A dual system has a .5 ohm resistor and a 5

ohm resistor as pictured and a points system has a special resistor

that varies with temperature.

Note: The “Orange Box” Mopar ECU was supposed to be a performance unit, but they don't seem to offer enough advantage to pay extra for one compared to other modern standard replacement units.

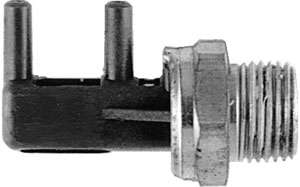

Ported

Vacuum Switch: A valve (switch) that is open or closed based on

engine temperature. This is a part found in almost every 1972 and

later Mopar engine. The valve is closed when cold and mounted to read

coolant temperature. Valves open between 95 and 130 degrees depending

on the year and their mounting location. The valve is intended to

prevent the vacuum advance pot from operating during engine

warm-up.

Ported

Vacuum Switch: A valve (switch) that is open or closed based on

engine temperature. This is a part found in almost every 1972 and

later Mopar engine. The valve is closed when cold and mounted to read

coolant temperature. Valves open between 95 and 130 degrees depending

on the year and their mounting location. The valve is intended to

prevent the vacuum advance pot from operating during engine

warm-up.

A very brief history of Slant Six ignition systems

Point

style ignition was used on pre 1972 Slant Six cars and trucks. Solid

state Electronic Ignition (EI) was used from 1972 -1983 on Slant Six

cars and trucks. V-8 models used the same wiring, but a different

distributor. Around 1978 the Lean Burn computer ignition system (LB)

was introduced in an effort to control pollution and reduce tune-up

frequency. The Lean Burn system was initially used on V-8 cars and

trucks. After 1980, Lean Burn was a Slant 6 option and by 1983 it was

used almost exclusively, but the Slant Six powered vehicles being

used at that time were primarily trucks & vans. Most auto parts

stores will show solid state electronic ignition as an option as late

as 1987 but it is not common to find it factory installed after

1983.

The Lean Burn system is not junk or trash as some people will complain. Simply put, a computer that lasts for 20 or more years attached to a hot shaking motor is an engineering marvel. Lean Burn computers in the later trucks were moved from on top of the engine's air cleaner to the fender, behind the battery, in an effort to reduce problems related to heat and vibration.

It seems to have worked because the Lean Burn computer in my 85 pickup outlasted the original motor. It would still be working if the mechanic I purchased the truck from hadn't removed most of the necessary pollution equipment and sensors that feed critical information to the computer. The Lean Burn computer can also control the fuel mixture in some models. Slant Six engines with factory Lean Burn requires the computer to control the carburetor unless an older "non lean" carb is to be used, such as a Super Six Carter BBD.

Removing

the Lean Burn system and replacing it with solid state electronic

ignition can still produce excellent results on pollution and

emissions tests. A slight change in fuel economy would only be

noticed if the Lean Burn system was in excellent working condition

(if any change was seen at all). The electronic ignition paves the

way for some special modifications such as Super Six carb rejetting,

performance ignition systems like MSD, and customized timing advance

curves. Basically you will be able to adjust functions that were once

controlled by the computer and, therefore, non-adjustable.

Removing

the Lean Burn system and replacing it with solid state electronic

ignition can still produce excellent results on pollution and

emissions tests. A slight change in fuel economy would only be

noticed if the Lean Burn system was in excellent working condition

(if any change was seen at all). The electronic ignition paves the

way for some special modifications such as Super Six carb rejetting,

performance ignition systems like MSD, and customized timing advance

curves. Basically you will be able to adjust functions that were once

controlled by the computer and, therefore, non-adjustable.

Parts and tools required for total Lean Burn conversion

Steps to the conversion

Disconnect the battery before doing any electrical system work or modifications.

Replace the carburetor (and manifold if needed) with the non-computer controlled replacement. Update the fuel lines and plug any unused vacuum ports on the new carb. The engine can be started at this point if it was running before the swap and rough carb testing / adjustment may be attempted.

Turn the engine to top dead center, remove distributor cap, and make sure the rotor of the distributor is positioned for the #1 plug to fire, (cylinder #1 compression stroke) not the #6 plug. (I like to point my distributor rotor at 12:30 (just slightly past "straight up" when looking over the fender) to make it easier to get back in the same place. - Chuck)

Remove the Lean Burn distributor and install the standard electronic distributor so the rotor is positioned the same way as the previous one you just took out.

Replace the cap and rotor on the new distributor.

Connect the distributor to the new wiring harness (the 2 prong connector).

Mount the ignition box to the firewall (or as desired). Be sure the ignition box is electrically grounded by its mounting hardware to the firewall (very important).

Remove the negative lead from the ignition coil (old wiring harness to Lean Burn).

Connect

the new wiring harness to the negative lead per the wiring diagram.

Connect the 12v+ lead from the new wiring to a source of power which is only on with the key turned to run. If removing the Lean Burn computer is desired, the positive power to the coil should be wired using the ballast resistor diagram. This involves providing straight 12v+ when the key is in the start position and ballast controlled voltage in the run position.

Remove the remaining Lean Burn equipment if desired.

Use

the timing light to adjust the distributor so that initial timing is

around 5 degrees before top dead center (btdc). Note that there is

another bolt on the bottom of the distributor that will allow you to

move the slotted plate for additional adjustment range. Troubleshoot.

You are my hero if you get it right on the first try.

(TIP: If you have the proper wrench, you can tighten the top

distributor bolt midway in the slot and then loosen the bolt

underneath the distributor to set the timing. This way you will have

the maximum adjustment each way with the top bolt after the bottom

bolt is tightened. - Chuck)

Adjust

the carb and check for proper mechanical timing advance operation.

Set the initial timing to your liking, so the engine doesn't ping but

still achieves good mechanical advance. Slant 6 engines seem to like

about 30 degrees of total timing (initial + mechanical), and some

reports say that as much as 15 degrees btdc still runs great without

idle misfire or high speed ping. Each motor is different, so you need

to experiment with different settings to find one that your engine

likes.

Route

new vacuum lines from the vacuum advance port of your carb to a

thermostatically controlled “ported vacuum switch” (usually

on the head by the upper radiator hose on new engines, or on the

radiator on old points systems). The valve should be closed when the

engine is cold and open when hot. Connect a hose from the other side

of the valve to the vacuum advance pot on the distributor. The vacuum

advance pot will need adjusting using a 3/32" Allen wrench inserted

into the port hole of the pot. Clockwise makes advance start sooner,

counterclockwise reduces advance.

"Round nosed" VA pots are not adjustable (pot shown in the middle).

The adjustable pots have a hex-shaped nose.

Tips and other notes

The 2 wire connection between the pickup in the distributor and ignition box is extremely low voltage. It is very important that the connections are clean and have solid contact. These wires should be routed to avoid interference from the coil and spark plug wires. These two wires cannot be reversed or poor engine performance will result (the engine will start and run but not well).

Don't wire the start position 12v+ directly to the starter solenoid. This would cause a reverse trickle in the run position and eventually fry your starter. A relay would need to be used, or some other tap into the wiring system would be required. Use the "Run" lead off your ignition switch.

The 12 volt coils used on Lean Burn engines didn't have ballast resistors. The story seems to be that the Lean Burn computer had an internal ballast resistor. An aftermarket coil that does not require an external ballast resistor could be used to eliminate the need for a relay and simplify the wiring. In general it is a good idea to use the factory coil designed for the ignition system being installed instead of re-using the coil from the old system.

Please send comments for improvement or corrections to: pmoran@potentialtech.com