You can use the space originally occupied by the carburetor and feed the plenum from the top through an elbow.

| Slant Six Forum https://www.slantsix.org/forum/ |

|

| Multi point Injection Intake Manifold https://www.slantsix.org/forum/viewtopic.php?t=59416 |

Page 2 of 3 |

| Author: | yostermercury [ Wed Apr 06, 2016 12:07 pm ] |

| Post subject: | |

No, sadly I haven't yet. This is day by day of the fabrication. I'll keep you guys as up to date as I can! We've got a lot left to do. We hope to have everything running by the Pigeon Forge Rod Run on the 15th and we hope to have some flow bench results off the full cnc version. The prototype was made with a holesaw and a portaband. |

|

| Author: | jcc [ Sun Apr 10, 2016 6:45 am ] |

| Post subject: | |

I like the craftsmanship of the project. I would have liked to see a steeper injector angle. I would have liked to see slightly longer runners. I understand the mentioned concern of others about air distribution, but I wonder if its that much of a "real" concern, since this is a dry manifold, and the as built rather large plenum should help minimize that potential issue, ie, anybody got data/numbers to back up their concern? |

|

| Author: | ProCycle [ Sun Apr 10, 2016 7:18 am ] |

| Post subject: | |

You can use the space originally occupied by the carburetor and feed the plenum from the top through an elbow.

|

|

| Author: | bmimken [ Tue Apr 19, 2016 4:37 pm ] |

| Post subject: | |

Glad to see someone making one of these! I especially like your thinking of getting the prototype finished, tested, and then making changes. In my opinion, I think most potential buyers would opt for the short runners over longer runners. There are a lot of members that have cramped engine bays with power brakes, power steering, and A/C. Target the daily driver crowd, then take your lessons learned and target the racing crowd. Brian |

|

| Author: | Matt Cramer [ Wed Apr 27, 2016 9:56 am ] |

| Post subject: | |

While I am not currently looking for an EFI intake setup, that is about what I paid to have a Clifford intake reworked for EFI, so the price is pretty reasonable. |

|

| Author: | Greg Ondayko [ Wed Apr 27, 2016 11:02 am ] |

| Post subject: | |

I would Like to see it work with sanden and c-171 Ac Compressors as well - For now I don't think the design will permit this type of AC compressor without relocating. This post (pictures) will show you what I mean a bit. http://www.slantsix.org/forum/viewtopic ... c&start=44 Thanks, Greg |

|

| Author: | Reed [ Wed Apr 27, 2016 2:09 pm ] |

| Post subject: | |

Since we are talking about dry manifolds, is there really any benefit to this log style manifold over a tradition curved plenum manifold? Why would one desire to purchase this log manifold over spending the same or less to have a stock or standard design manifold machined for injector bungs? Just curious. It seems to me that a hyperpak woudl be a great choice for a fuel injection intake design since all the fuel puddling issues would be eliminated. |

|

| Author: | yostermercury [ Fri Apr 29, 2016 10:12 am ] |

| Post subject: | |

Our goals are alot like what bmimken stated. We are shooting for a daily driver crowd, a hyperpack manifold will not fit on as many applications as a shorter runner manifold. The Log is a simplistic design that will be very strong and should provide an upgrade path for a turbo if wished. Greg Ondayko, I would love to try and fit one of those units up as for now we are looking at focusing on OE Vehicles. We are thinking about a race manifold with several changes including: runner length, placement, strength for turbo charging and other modifications. We have also contemplated a stainless turbo header. For now, however, we think it is best for us to concentrate on a good first product that will fit a wide enough market and that is competitively priced. We are looking into including a few extras with the kit such as a fuel pump block off, exhaust manifold shield/block off, and possible mounting hardware (more on that later). Thanks for the feed back guys! |

|

| Author: | emsvitil [ Fri Apr 29, 2016 2:47 pm ] |

| Post subject: | |

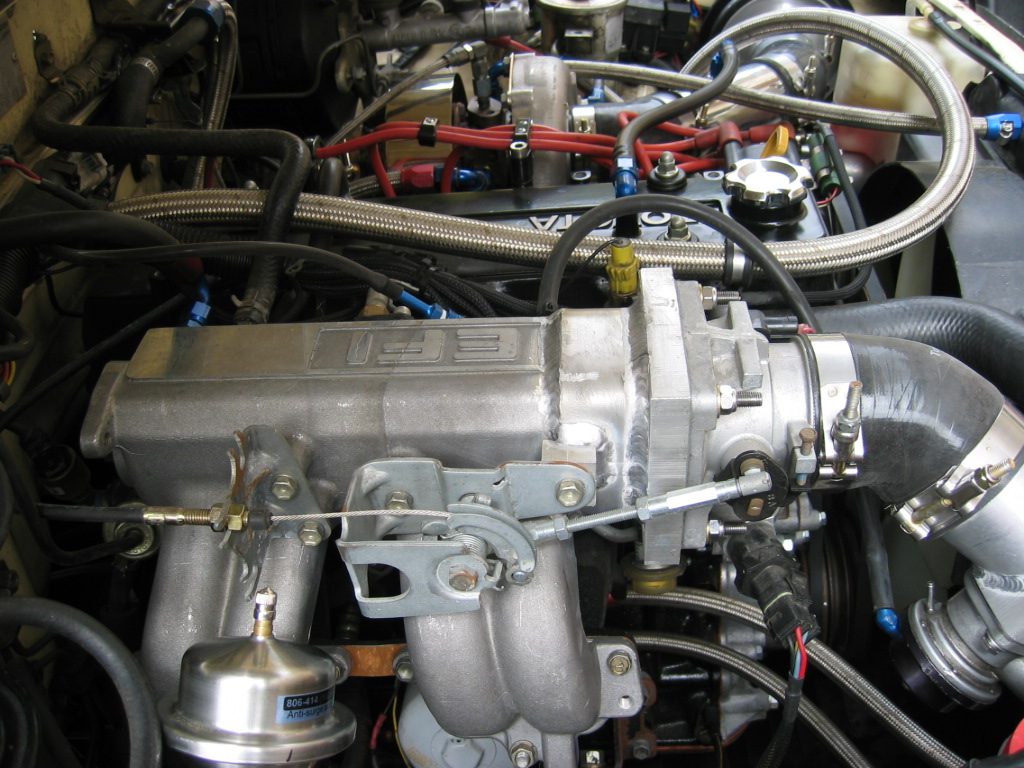

For runner length you could put U-bends in the runners so the manifold folds on itself. Toyota 22RE:

|

|

| Author: | jcc [ Sat May 14, 2016 10:57 am ] |

| Post subject: | |

I'm not seeing the 45? degree injector angle, am I missing something? And "running"means you are better then me. |

|

| Author: | yostermercury [ Mon May 16, 2016 9:42 am ] |

| Post subject: | |

JCC: Correct you're not seeing a 45 degree injector angle, that will be on the next version. We just wanted to install this prototype to show everyone that we are serious and we wanted to test how well the throttle body, injectors, sensors, megasquirt, EDIS, and everything else would work. As of right now we have about 50 miles on the current setup, we are averaging 27-33 MPG when cruising at about 45-55 with rolling hills. Keep in mind we only have about 50 miles. We have been measuring fuel at the fuel cell and the car is mostly stripped (no carpet, no ac, the trunk has been back halfed). The Dart has stock 904 transmission and stock 2.76 rear end gear. We are keeping a good accurate log on fuel economy, but its a little difficult with WOT pulls. |

|

| Author: | jcc [ Tue May 17, 2016 11:54 am ] |

| Post subject: | |

This normally is not a big concern for most, but on the layout of a slant six, with an effectively "dry" intake with EFI, I'd be real curious what the readings are from the IAT, or more directly, what intake heating takes place that the fuel in a carburetor set-up would be cooled that a port efi has a harder time achieving? |

|

| Author: | Reed [ Tue May 17, 2016 12:06 pm ] |

| Post subject: | |

I would think that any reasonable EFI system would abandon the factory intake heating provisions and run headers, Dutra Duals, or at the very least a stock exhaust manifold with the "tower" chopped off and the hole brazed/welded over. Intake manifold heat just isn't necessary with port EFI (TBI is a different story since the intake anifold is still wet). |

|

| Page 2 of 3 | All times are UTC-08:00 |

| Powered by phpBB® Forum Software © phpBB Limited https://www.phpbb.com/ |

|