Quote:

A (much) easier workaround to achieve the same goal: "winged" wide rotor tips that could easily be cut out of brass and swapped onto shelf-stock rotors.

| Slant Six Forum https://www.slantsix.org/forum/ |

|

| Distributor Cap Terminal To Rotor Clearance https://www.slantsix.org/forum/viewtopic.php?t=60552 |

Page 2 of 7 |

| Author: | SlantSixDan [ Wed Jan 04, 2017 8:11 pm ] |

| Post subject: | |

Well, the wider contacts mean there's good rotor/cap terminal alignment through a wider range of spark advance and/or a longer spark duration, which means less arcing under the cap, which is usually counted as a good thing. Most of a decade ago I spoke with Mitech Ignition (of Welland, Ontario) and they weren't opposed to making wide-contact distributor caps "if the volume is enough to make it worthwhile", which it almost certainly is not. Mitech went out of business in 2010 or so. A (much) easier workaround to achieve the same goal: "winged" wide rotor tips that could easily be cut out of brass and swapped onto shelf-stock rotors. Previous discussion here and here. Then all we'd have to do is home in on an easy-to-buy, high-quality current-production cap with brass or copper contacts. There are still some candidates that don't look to have been tested yet. If we could find a cap that's consistently ground on-centre even if its contact dimensions aren't optimal for off-the-shelf rotors, that would be fine, because we'd be tailor-making a rotor to suit. |

|

| Author: | Reed [ Wed Jan 04, 2017 8:16 pm ] |

| Post subject: | |

Quote: A (much) easier workaround to achieve the same goal: "winged" wide rotor tips that could easily be cut out of brass and swapped onto shelf-stock rotors.

|

|

| Author: | SlantSixDan [ Wed Jan 04, 2017 8:45 pm ] |

| Post subject: | |

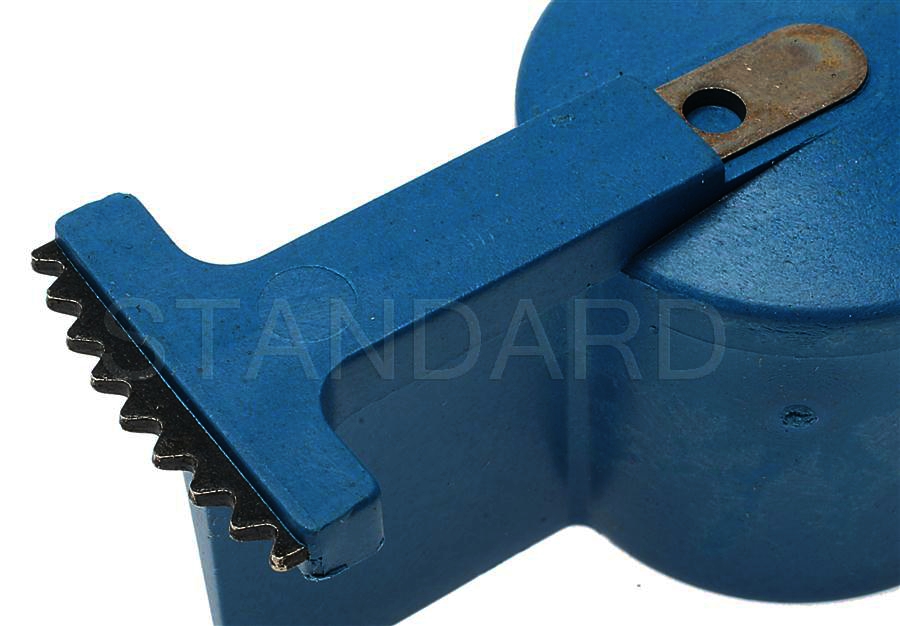

For that matter, parts could be robbed right off of existing rotors, cut and drilled as necessary, and swapped onto a Chrysler rotor. Here's a Standard AL178 for old Prestolite applications:  Here's a CH310 for Chrysler/Mitsu 3.0 V6 (this is the fancy version with the toothed and encased contact:  Here's the CH310T budget version with the exposed and non-toothed contact:  Here's DU315 for '80s Renaults with Ducellier distributors:  Here's FD117 for Ford applications....geeze, that contact looks like it might be real close to a direct swap onto the Chrysler rotor!  Here's FD308, another Ford piece with another promising contact:  And…erm…whoah, stop the presses, here's IH318, which is called out for use on International (1964-1980) and Plymouth (1974). Contact tip isn't as wide as some of these others I've posted, but it looks like it could be a drop-in. Is it shorter or longer than a CH303? Donno, but Standard's database calls it out as compatible with distributor caps CH-410 and CH-409, that is the Slant-6 and V8 distributor cap, respectively. ?! Looks like it's got some Chrysler part number equivalents, too: 2875852 and 3620769, neither of which appears in the passenger car FPCs for years relevant to those part numbers' genesis. Truck/van, maybe? Someone buy one of these and check it out:  This isn't an exhaustive list, either. |

|

| Author: | Reed [ Wed Jan 04, 2017 8:49 pm ] |

| Post subject: | |

Dammit Dan, you need to stop putting ideas in my head! You are an evil fun-project-pusher! This would be a totally easy thing to fabricate with nothing more than basic tools. I would love to see some ignition computer scans of the HEI conversion with one of these home-brew rotors. |

|

| Author: | SlantSixDan [ Wed Jan 04, 2017 9:07 pm ] |

| Post subject: | |

Update: 2875852 and 3620769 are apparently '74-'75 Dodge medium- and heavy-duty truck rotors. Should be drop-in for the Slant-6. Now all that remains is to buy (Standard IH318) and compare/measure. DonPal…? |

|

| Author: | DonPal [ Thu Jan 05, 2017 3:13 am ] |

| Post subject: | |

I'll check the clearances of the wider IH318 rotor but is it extended like the MO3000? Otherwise the decreased .060 will hurt the wide rotor concept test? Making our own extended wide rotor about .010 longer than a MO 3000 sounds like the real trick. I'll make up one and get the secondary voltage since that has the most promise with a decently machined cap.....of which the test shows occurs once in a dozen times....ugh. The MO6 cap looks readily obtainable as well as the late 60's chrysler cap for establishing dimensions Chrysler was honed in on.....and the resulting secondary voltages. So I can see a few more rotor and caps test needed. The weather is a factor here as even though measuring is done inside..... secondary voltages are outside.....I'll post the measurements as I get the caps and the secondary voltages as soon as mother nature gets us back above 40. |

|

| Author: | SlantSixDan [ Thu Jan 05, 2017 10:16 am ] |

| Post subject: | |

Quote: I'll check the clearances of the wider IH318 rotor but is it extended like the MO3000?

Don't know -- that's one of the things to be measured about it!Quote: Otherwise the decreased .060 will hurt the wide rotor concept test?

I don't know that, either; it depends on how it interfaces with the cap contacts (which in turn depends on what cap we're testing it against, right?)Quote: The MO6 cap looks readily obtainable

There's that one on eBay for $15.Quote: as well as the late 60's chrysler cap for establishing dimensions Chrysler was honed in on

I see one on eBay for $50 (pfft). Probably ought to get hold of the 2098770 rotor that was meant to be used with that cap, too. Send me a PM if you'd like me to work on tracking one down. |

|

| Author: | Greg Ondayko [ Thu Jan 05, 2017 1:41 pm ] |

| Post subject: | |

Excellent resource list here. Dan can you explain why the ch 310 has the teeth? Thanks! Greg |

|

| Author: | SlantSixDan [ Thu Jan 05, 2017 2:40 pm ] |

| Post subject: | |

Sparks jump easier from pointy things. |

|

| Author: | Greg Ondayko [ Thu Jan 05, 2017 5:09 pm ] |

| Post subject: | |

Makes sense. Could that mod be applied to other rotors if done with decent tooling? Thanks again for the info. Greg |

|

| Author: | SlantSixDan [ Thu Jan 05, 2017 5:16 pm ] |

| Post subject: | |

Quote: Could that mod be applied to other rotors if done with decent tooling?

Don't see why not!

|

|

| Author: | DusterIdiot [ Thu Jan 05, 2017 5:51 pm ] |

| Post subject: | Lol... |

Quote: Dan can you explain why the ch 310 has the teeth?

In the best Adam Sandler Waterboy voice I can muster:"Mama says, that the rotor has teeth, because it's smiling that some slixer is going to install it in a 225 and whup on some poor V-8..." Sorry couldn't resist... |

|

| Author: | DonPal [ Mon Jan 09, 2017 2:04 pm ] |

| Post subject: | Added More Data & Brought Table To this Point |

United CC-611X data added---close/almost hit rotor Std IH-318 does not fit on slant distributor shaft (too small ID) MO 6 and 2642986 data added to 60's info (note avg. gap at .020) Below table has all the original & latest data plus provisions for the 60's caps. Also started table for Secondary Voltage Tests of significant data cases and places to add upcoming significant data cases. Slant Six Distributor Cap Terminal To Rotor Tip Gaps Table shows results with Exchlin MO3000 Rotor (uln) CAP MODEL CAP# MAX MIN ECC Echlin MO 40 1 .030 .013 .008 Echlin MO 40 2 .038 .010 .014 Echlin MO 40 3 .041 .012 .014 Echlin MO 40 4 .022 .017 .002 Echlin MO 40 5 .034 .014 .010 Echlin MO 40 6 .038 .008 .015 Echlin MO 40 7 .040 .015 .012 Echlin MO 40 8 .032 .015 .008 Echlin MO 40 9 .041 .009 .016 Echlin MO 40 10 .030 .025 .003 STND CH-410 1 .030 .008 .011 STND CH-403X 1 .040 .015 .012 AIRTX 5D1022A 1 .030 .005 .012 REMANUF Echlin 9 .018 .012 .001 UNITED CC611X 1 .040 .006 .017 1960's & Early 70's Typical Gaps ECH MO 6/1838516 1 .028 .013 .007 2642986/1838516 1 .027 .010 .008 For Different Rotors measured: Echlin MO 13 add .057 to all gaps CARQUEST D147P add .056 to all gaps MOPAR 1838516 subtract .008 to all gaps (interference fit on Echlin #6 & Standard #1) All dimensions in inches Secondary Voltages THE DATA CASE GAP SEC VOLT The Worst Gap .114 22,000 IH-318 rotor Medium Gap .025 9,000 60's Dbl. Width .028 2,200 Machined Gap .018 5,000 Mod IH318 Will put IH-318 rotor tip on different rotor and adjust for .015 avg gaps Will also test 60's caps with other period rotor. |

|

| Author: | emsvitil [ Mon Jan 09, 2017 4:03 pm ] |

| Post subject: | |

What are you measuring with the ECC(entric) measurement? |

|

| Author: | DonPal [ Mon Jan 09, 2017 4:58 pm ] |

| Post subject: | |

"What are you measuring with the ECC(entric) measurement?" Indirectly measuring offset of the center of the cap versus the center of the distributor shaft Said another way if we cut the distributor and distributor cap in half we could measure a difference between the center of the distributor cap at rotor position and the center of the distributor shaft at that same position (or elevation) Detailed Proceedure: 1) Rotor is the gauge of a fixed length rotating about the distributor shaft centerline. 2) Record all gaps between rotor and each terminal and record on the cap 3)Scan the cap for the highest and lowest value 4)Note that in every case so far they are diametrically opposite ie terminals 2 and 5 or 1 and 6 etc. 5)The center line of the distributor is furthest away from the biggest gap terminal 6)Take the last case where the biggest gap was .040 and the least gap was .006 then if the distributor shaft center was .017 further away from the .040 gap terminal it would be .017 closer to the .006 terminal 7) the eccentricity direction is defined by the two most opposing gap differences Take the cap off the jig and turn it 180 deg and all the extreme gaps change opposite to what they were as the cap "lean" put the center of the cap to the other side. Not measured directly but inferred from the gaps determined by our measuring tools (the rotor and feeler gauge). |

|

| Page 2 of 7 | All times are UTC-08:00 |

| Powered by phpBB® Forum Software © phpBB Limited https://www.phpbb.com/ |

|