Quote:

Assuming your rings are OK, you should be fine. Did you do a compression test, by chance (engine warmed up), before you tore it down?

Here is the link to the Howards cam discussion:

http://slantsix.org/forum/viewtopic.php?f=19&t=62844

The search function is very helpful on this board. If you search "howards" then that thread comes right up.

Lou

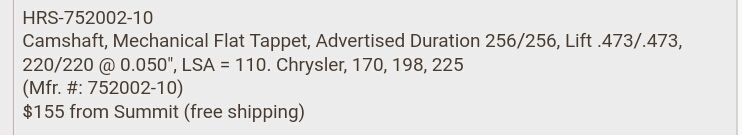

Thanks Lou, those Howard cam specs look pretty good for a street 225. CheersHere is the link to the Howards cam discussion:

http://slantsix.org/forum/viewtopic.php?f=19&t=62844

The search function is very helpful on this board. If you search "howards" then that thread comes right up.

Lou