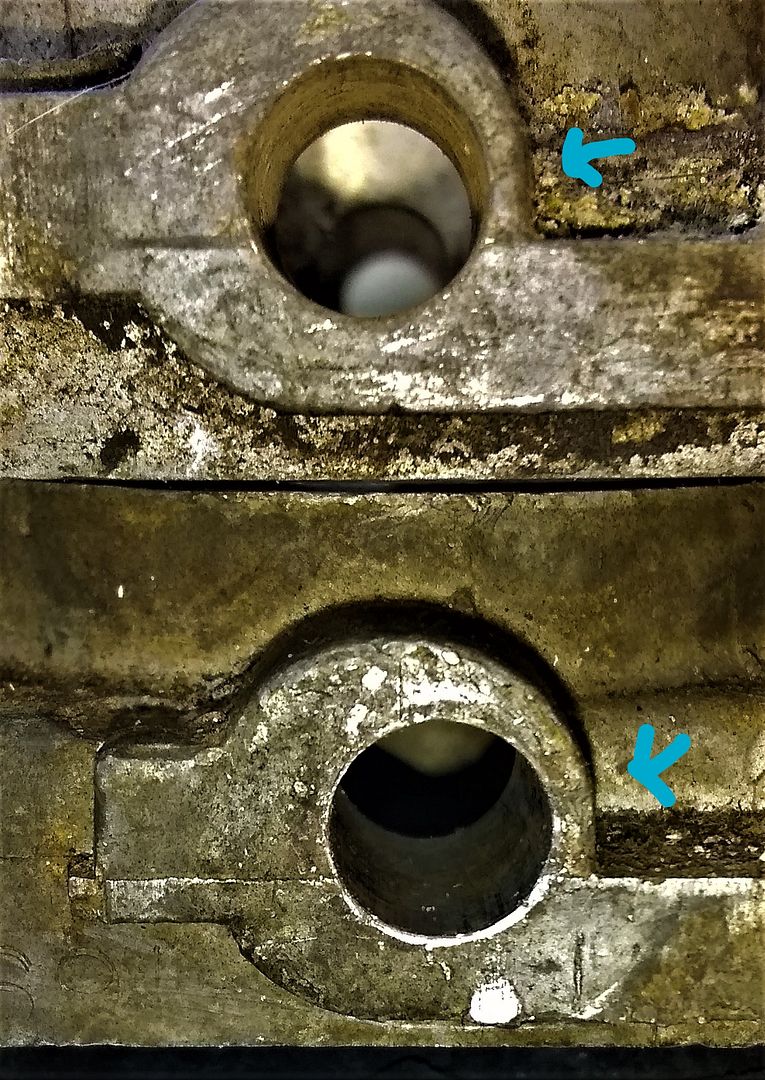

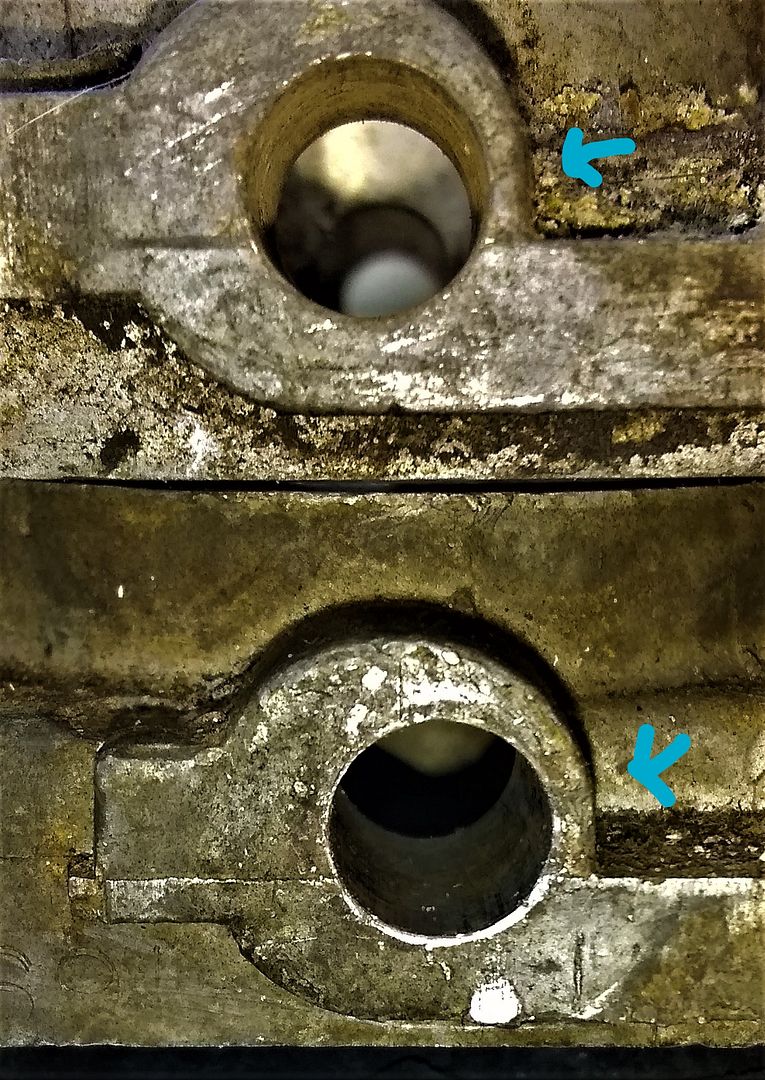

thin spots

| Slant Six Forum https://www.slantsix.org/forum/ |

|

| Carter BBD identification and evaluation https://www.slantsix.org/forum/viewtopic.php?t=65415 |

Page 2 of 2 |

| Author: | Jase [ Sat Oct 17, 2020 6:41 pm ] |

| Post subject: | Re: Carter BBD identification and evaluation |

Quote: I ordered the bushing kit from eBay.

Not sure how to use a reamer to get to the size you need.... I'm sure someone has the experience to pull it off.. I am about to order the following, It is more expensive, but appears easy to accomplish as well. I think I have seen the same or similar type product elsewhere as well: I also took out the throttle plates. Somewhat alarmingly, the screws weren't actually staked, but they were tight all the way out. I don't know if that was thread sealer or they are just made tight like valve adjustment screws. One actually broke off about halfway out and I had to drill it out. When I got the shaft out, I discovered that there isn't much room for a new bushing in the throttle body (I measured the wall thickness at 0.067" at the thinnest point). I'm not sure if this is going to work... https://cliffshighperformance.com/produ ... ushing-kit |

|

| Author: | rich006 [ Sat Oct 17, 2020 7:42 pm ] |

| Post subject: | Re: Carter BBD identification and evaluation |

The kit Reed linked on eBay arrived today. It includes a reaming bit with a shaft that fits where the throttle shaft would go, so that the enlarged hole is automatically straight. Unfortunately, as I feared, there's not enough metal around the existing hole to make space for the new bushing. The bushing might stay in place but it definitely will not be completely surrounded by aluminum. I don't know how realistic it is to try to build up the throttle body before reaming. If anyone has tried that before, I'd love to hear how you did it. |

|

| Author: | matv91 [ Tue Oct 20, 2020 7:44 am ] |

| Post subject: | Re: Carter BBD identification and evaluation |

thin spots

|

|

| Author: | matv91 [ Tue Oct 20, 2020 8:15 am ] |

| Post subject: | Re: Carter BBD identification and evaluation |

test weld, is aluminum will weld

|

|

| Author: | matv91 [ Tue Oct 20, 2020 8:18 am ] |

| Post subject: | Re: Carter BBD identification and evaluation |

|

|

| Author: | matv91 [ Tue Oct 20, 2020 8:24 am ] |

| Post subject: | Re: Carter BBD identification and evaluation |

Clean up prep

|

|

| Author: | matv91 [ Tue Oct 20, 2020 8:29 am ] |

| Post subject: | Re: Carter BBD identification and evaluation |

Build up weld

|

|

| Author: | matv91 [ Tue Oct 20, 2020 8:31 am ] |

| Post subject: | Re: Carter BBD identification and evaluation |

Done

|

|

| Author: | rich006 [ Tue Oct 20, 2020 8:50 am ] |

| Post subject: | Re: Carter BBD identification and evaluation |

Quote: Done

Thanks for the pictures! I worked on this over the weekend and my propane torch couldn't get the throttle body hot enough to melt the brazing rod. It's good to know I was on the right track with my approach, but I think I would have needed a MAP torch to make it work.I also realized the throttle shaft itself has significant pitting, so there's never going to be a great seal even with a new bushing (unless I were to grind it down, but then I'd need a different size bushing, and at some point it's just too much to do). Also, the bill for rebuild kit plus float plus idle mixture screws plus throttle plate screws (I broke one) was going to be over $50 and there's no telling if the carburetor would ever work well anyway. I went ahead and ordered a brand-new Chinese BBD on Amazon for $80 and I'll post how it goes. |

|

| Page 2 of 2 | All times are UTC-08:00 |

| Powered by phpBB® Forum Software © phpBB Limited https://www.phpbb.com/ |

|