Quote:

I am not familiar with the al block, but could the deck be cut to clean everything up and then O-ring the head? I Am thinking the o-ring will allow some compliance for thermal expansion differences and be a lot better than the original head gasket.

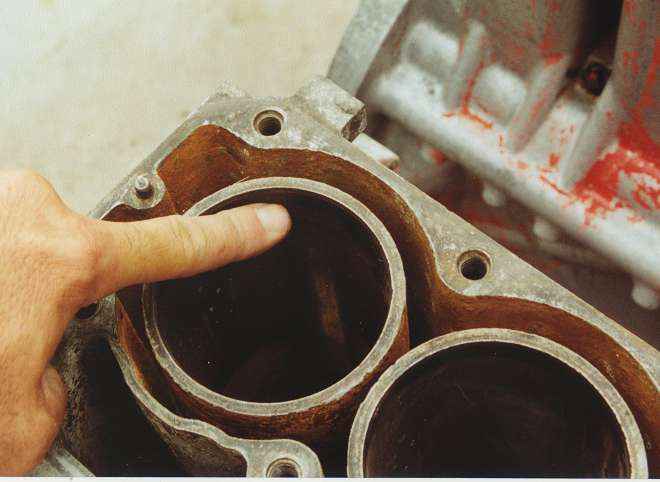

The block "deck" looks like this: