Quote:

So...I made a 1 inch impeller HV die cast aluminum oil pump by adding a spacer to a factory unit.

Dutra does it again!

How'd you make the spacer?

| Slant Six Forum https://www.slantsix.org/forum/ |

|

| Twiggy - Long Rod Aluminum Block Engine Build-up https://www.slantsix.org/forum/viewtopic.php?t=23948 |

Page 11 of 25 |

| Author: | SlantSixDan [ Tue Aug 21, 2007 9:57 am ] |

| Post subject: | |

Quote: So...I made a 1 inch impeller HV die cast aluminum oil pump by adding a spacer to a factory unit.

Dutra does it again!    How'd you make the spacer? |

|

| Author: | argentina-slantsixer [ Tue Aug 21, 2007 10:10 am ] |

| Post subject: | |

cutting a donor pump's body? |

|

| Author: | AnotherSix [ Tue Aug 21, 2007 10:26 am ] |

| Post subject: | |

That's a nice way to do that. You get to use o-rings to seal both sides too, right? If you need a big pump you need it, I just like to avoid it whenever possible. I was not thinking at all about the engine not using cam bearings. With all the welding, is the cam bore still true enough? How bad did it get? I would have to check, but I think some of the aluminum v-8 blocks take standard cam bearings. I can see that retention might be a problem with a steel backed bearing in an aluminum block, maybe they pin them. Have you looked at line boring the cam bore and using bearings? Maybe there is not even enough material to do this. If that is a possibility it would also cut down on the oil pressure loss. Custom aluminum inserts bored to size after being installed might cost a fortune. Not really the right time to think about this, but now I am wondering how this weighed out in your planning, or are you just stuck with the cam bores you have?. |

|

| Author: | Doc [ Tue Aug 21, 2007 12:31 pm ] |

| Post subject: | |

Quote: That's a nice way to do that. You get to use o-rings to seal both sides too, right? If you need a big pump you need it, I just like to avoid it whenever possible.

I am the same way, I use the standard size pump most of the time. The "loose" cam bearings are the main reason to use the thicker impeller pump and to take the time and extra work needed to make-up a special aluminum bodied HV oil pump.Quote: I was not thinking at all about the engine not using cam bearings. With all the welding, is the cam bore still true enough? How bad did it get?

There is .001 in wear and .003 in warpage... the good news is that the wear is on one side of the cam bores and the warp is in a different direction... the cam still slides-in and turns freely but there are some high and low spots. It is hard to know what will happen after this engine gets run for a while and that cam "settles-in". (knocks down the high spots) Quote: Have you looked at line boring the cam bore and using bearings? Maybe there is not even enough material to do this. If that is a possibility it would also cut down on the oil pressure loss. Custom aluminum inserts bored to size after being installed might cost a fortune. Not really the right time to think about this, but now I am wondering how this weighed out in your planning, or are you just stuck with the cam bores you have?.

We looked at the repair options you listed and yes, we can jig bore the cam bores oversize and install conventional cam bearings, there is room to do this. The decision was to run the current condition we have and see what happens... it may not be an issue if the warp helps position the cam to keep the oil feed holes covered. (and it looks like it will for cam journals 2 & 3) The HV oil pump is the "insurance policy" that will be able to compensate for extra oil pressure loss in the cam journal area. Yes, another decision, another compromise but I don't think it's a "show stopper". DD |

|

| Author: | Doc [ Tue Aug 21, 2007 12:38 pm ] |

| Post subject: | |

Quote: Quote: So...I made a 1 inch impeller HV die cast aluminum oil pump by adding a spacer to a factory unit.

Dutra does it again!    How'd you make the spacer? The spacer is sealed by o-rings on both sides but I actually epoxyed the spacer to the pump housing to insure proper alignment... forever. (the spacer to pump body o-ring is now incapsulated in epoxy) DD |

|

| Author: | Matt Cramer [ Tue Aug 21, 2007 12:58 pm ] |

| Post subject: | |

Thanks, Doc! I'll see about setting up a custom order for that cam once I have the original turbo motor up and running - then I'll see about getting parts for a rebuild. |

|

| Author: | 440_Magnum [ Tue Aug 21, 2007 2:31 pm ] |

| Post subject: | |

What a cool thread. I wish to heck there was a forum like this for guys that build big-blocks :-/ I was just looking back at the first page of this one, and noticed that someone commented on the lifter bores for the AlSl6 looking "weak." I hadn't even thought of that, but.... well... yeah! I sure wouldn't want to run a roller cam with bores like that, but a slider should be fine because a slider limits the amount of lateral "plucking" force that the cam lobe can apply to the bottom of the lifter. An old MML acquaintance (Brian Stroud, some of y'all probably have crossed paths with him in the Mopar world) learned that big roller cams put a lot more side-load on lifters than sliders the hard way. Ripped an exhaust lifter bore right out of the *cast iron* block on his 440. If you stop and think about it, the roller lifter can tolerate so much more lift rate that the potential exsits for many many times the sideways force that a slider lifter gets. Combine that with the fact that there's one lifter bore in a B/RB (#1 exhaust, IIRC) that has less meat around it than any of the others, and the meat it does have gets stressed in tension by the side-thrust of the cam on the lifter as the roller starts up those uber-steep ramps. Ka-pow. And of course when a lifter (and bore) drops into a spinning crank, other Really Bad Things (tm) happen too.... |

|

| Author: | DionR [ Tue Aug 21, 2007 4:44 pm ] |

| Post subject: | |

Quote: Really Bad Things (tm)

So where do I send my royalty payments, 'cuz I wanna use that. |

|

| Author: | Doctor Dodge [ Tue Aug 21, 2007 9:51 pm ] |

| Post subject: | |

Quote: I think the major advantage of doing this is not the weight saving, but being able to use the 6 bolt pump housing. This will close off the unused pump pocket and allow the pump gear oiling mod.

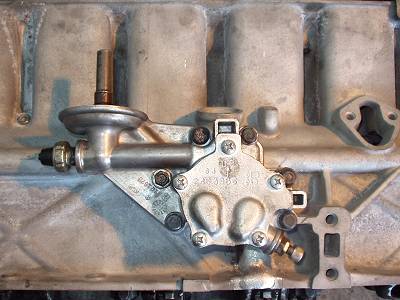

Yes, all the alm. die cast oil pumps have the 3 pockets and 6 bolt holes needed to install and feed the cam gear oiler tube.Here is a view of the anti-drainback feed tube leading into the "unused" block pocket that now contains the oiler. The tall tube keeps the oil in the main gallery from draining-out thru this path after shutdown. Notice anything else different about this pump? DD

|

|

| Author: | DionR [ Tue Aug 21, 2007 10:00 pm ] |

| Post subject: | |

Quote: Notice anything else different about this pump?

Knurled knob on the oil pressure spring?

|

|

| Author: | Doctor Dodge [ Tue Aug 21, 2007 10:13 pm ] |

| Post subject: | |

You are right... a knob to do oil pressure relief valve / oil pressure adjustment with-out having to remove the plug and spring. It is a shame that it adds weight! DD

|

|

| Author: | slantasaurus [ Tue Aug 21, 2007 11:32 pm ] |

| Post subject: | |

With the wear/warpage in the cam journals are you concerned that it may cause oil pump/cam/distributor drive failure that has been plaugeing other peoples engines ??? I know that has been a problem area of late. I was thinking about mocking up just the cam, oil pump, and distributor when I get around to building my engine (sometime in the distant future) to see if I could find any binding that might be a problem. I'm sure you have already thought this through, but like I said earlier, I seek knowlage from the master. |

|

| Author: | Doc [ Wed Aug 22, 2007 7:31 am ] |

| Post subject: | |

Yes, one of the first steps I do on a SL6 engine build is to check the oil pump to cam gear mesh. I do not worry about the distributor if it has the nylon gear. ( I do check metal distributor gears ) My check on Twiggy and a photo is on page 3 of this thread. The mesh looks pretty good pattern wise, there is a bit more backlash between the two gears due to the warpage but it's not excessive... actually, some say that additional backlash between these gears is good, it lets more oil in and helps the gears run cooler. DD |

|

| Author: | SlantSixDan [ Wed Aug 22, 2007 9:21 am ] |

| Post subject: | |

Doc, I'm not sure I understand how the small-diameter antidrainback tube works. |

|

| Author: | Doc [ Wed Aug 22, 2007 11:40 am ] |

| Post subject: | |

The small oil feed tube works like a "pea trap" in your plumbing fixtures, the bottom of the tube is below the oil squarter's outlet level and stays covered with oil in the pocket so air does not go up into the main oil gallery. The top of the tube does not allow the oil to flow down into the oiler's mounting pocket and out the oiler tube unless it is under pressure. DD |

|

| Page 11 of 25 | All times are UTC-08:00 |

| Powered by phpBB® Forum Software © phpBB Limited https://www.phpbb.com/ |

|