Here are the Next Step(s) in the Process:

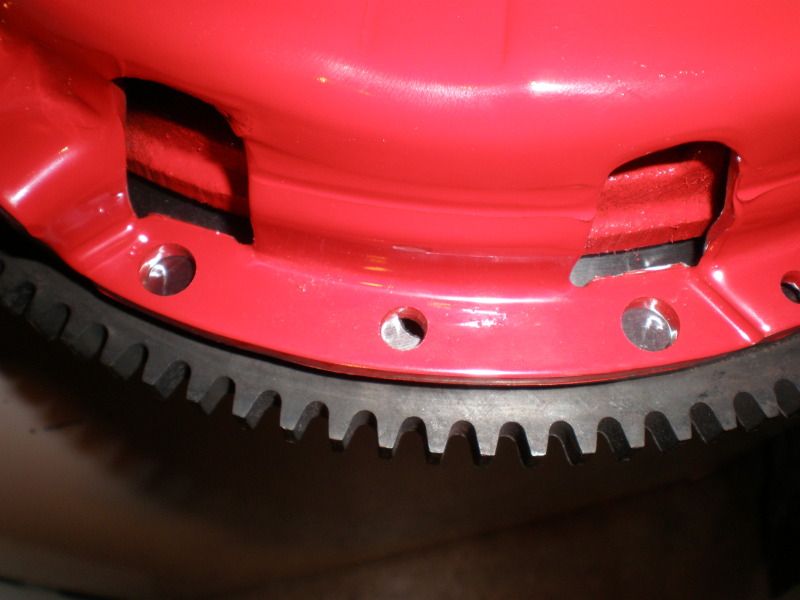

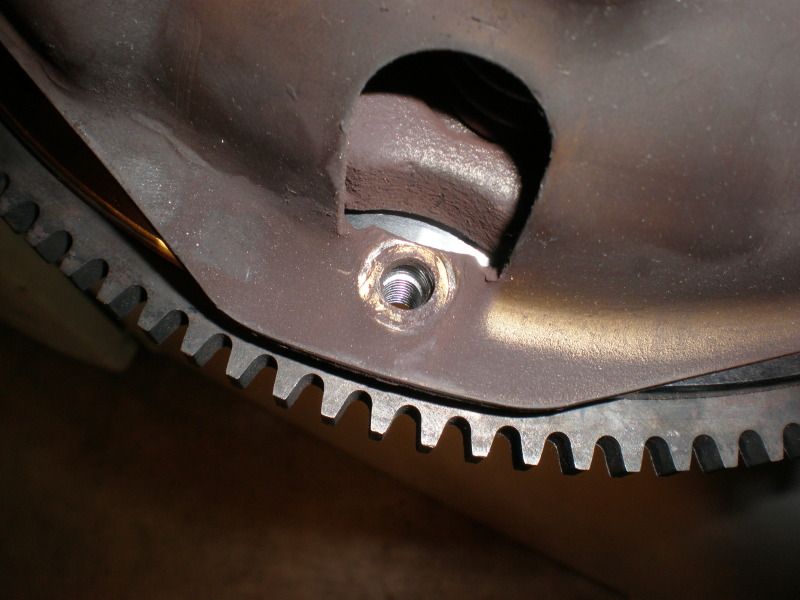

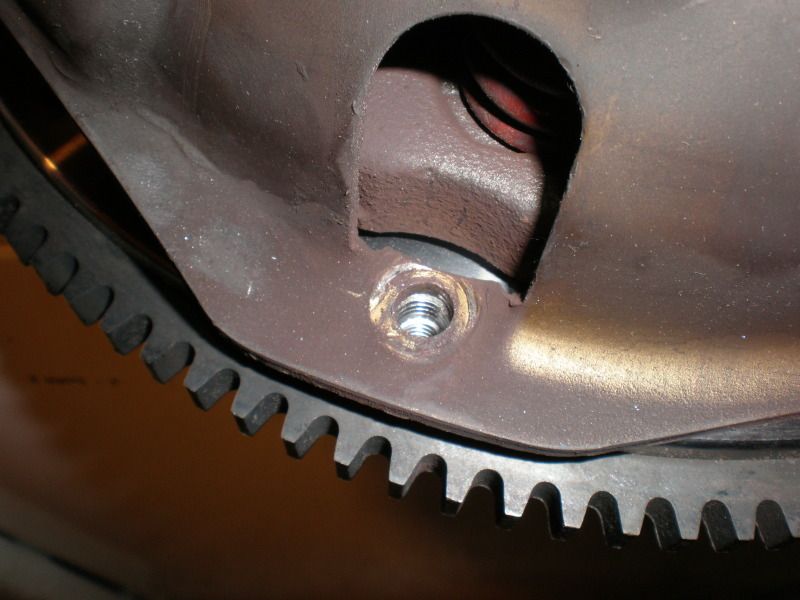

Before Re- assembly of the clutch / PP / Flywheel I like to Clean the Bell Housing inside and out before the Reinstall:

Using The parts washer All the old greasy Gunk and clutch dust are removed from the stuff I am going to put back into the car:

The stuff is clean Now!

Even though I am not re-using the Old Flywheel on this project; I am cleaning it and Sending it to the machine shop for surfacing; I will stash it away and Possibly re-use it on another project Later

For This pressure Plate Install I will have to shim the Clutch Fork Pivot Closer to the Flywheel / Engine - If you are using a stock type Pressure Plate this step is NOT Needed.

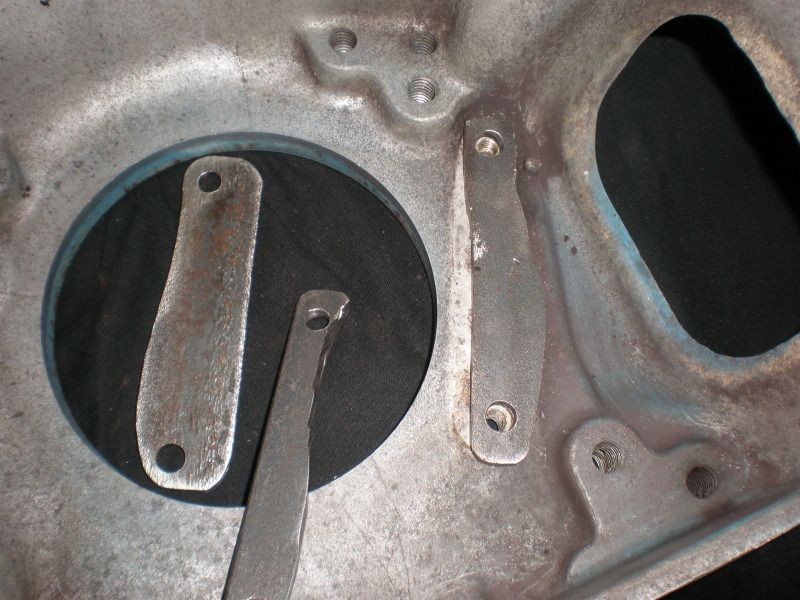

I removed the Old Clutch Fork Pivot and Used it to layout some bits of Steel to make the spacer.

I marked the holes and Got the general outline for the Spacers.

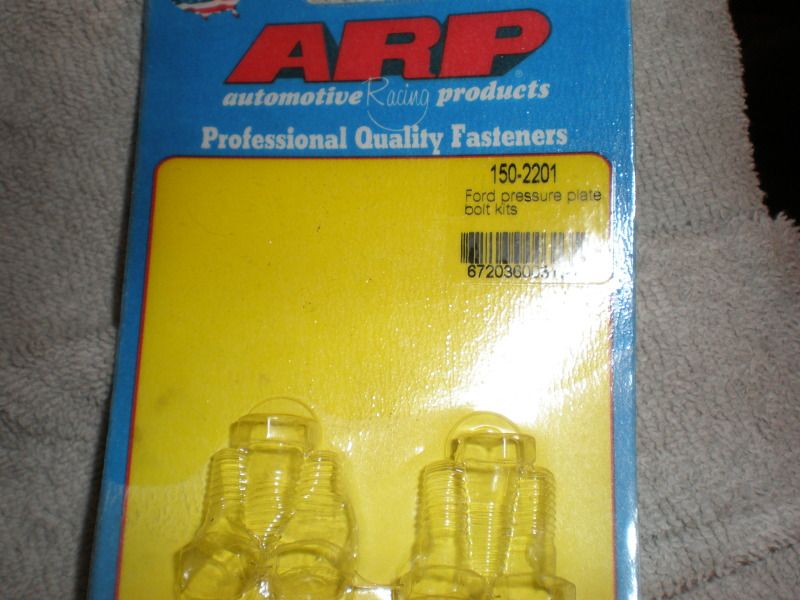

Also the Stock Bolts That hold the Fork Pivot will be waaay to short so I will replace those too.

Here are some shots of the Spacers I made - I was using some left over angle Iron and Made the spacers - No they are Not Billet, nor are they pretty but they will do the job.

All 3 spacers are done; they measure about 1/2 Inch which should be just right for this setup - I can always unbolt the fork pivot and add or subtract the spacers to get it right.

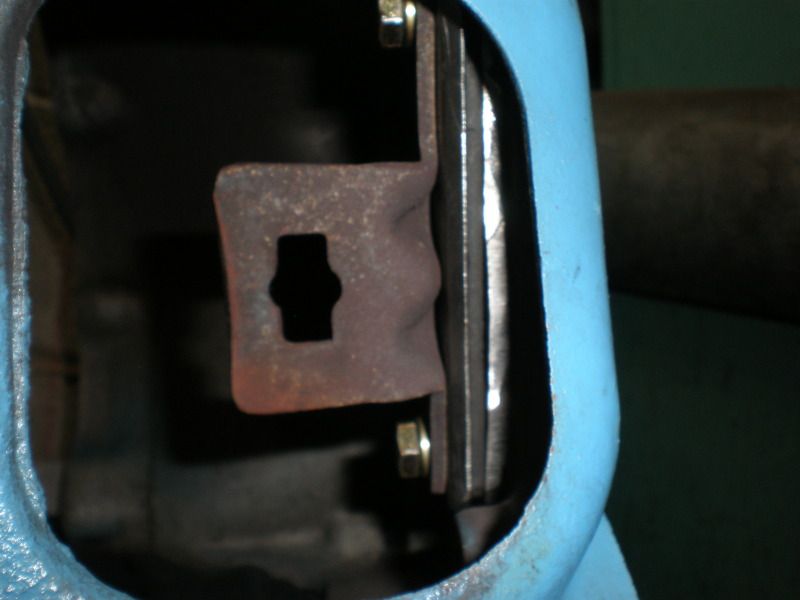

Next are some shots will all the spacers and Clutch fork pivot installed and bolted down.. Notice the longer bolts needed for this.

All complete and A New Throwout bearing too.. I usually Toss In a New TO Bearing if I have the tranny out and I dont want to do the job again anytime soon.

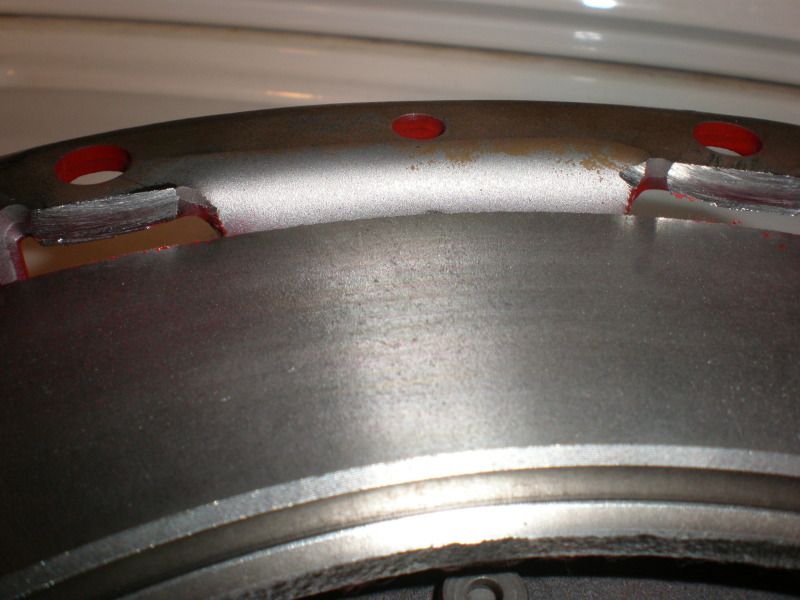

Now Lets take a look at that 10" Ford/Mazda Pressure Plate from McLeod.

I had some trouble with the clutch hitting / binding on the bolt hole material of the Pressure Plate Hat when I did this install on the dart back in 2006 - It is much easier to cut / grind these tabs before the install raher than after.

The Pen points to the Black line where I am going to make the cuts;

This will happen on 6 of the mounting points.

Tools I used to do this hack:

Bits Removed - Not Much but enough to alleviate hassles later.

Photos of the PP after Cutting the six Little tabs off:

Pen Points to where the cuts were made:

Next:

Test fitting the PP / Clutch / Flywheel / Clutch rod etc..

I have to Wait for the McLeod 464001 Flywheel to come in to do this.

Greg