Quote: MAJOR question: how are you defining where you "think the curve should be"? There's been a lot of talk about why an ideal WOT curve varies from one engine to another and from one car to another, all very valid points, but I've seen no mention from anyone about testing a particular combination to determine its own theoretical ideal. Some people have mentioned listening for pinging-- but by the time that's audible (even to instruments), you're already slightly past the point of maximum power (and you're subjecting the engine to much more stress than it needs because the cylinder pressure peak is occuring too early.) There is a much better way, that Dr. Chris Jacobs describes quite well in his book, "The Doctor's Guide to Optimizing Ignitions," but I haven't seen any discussion, so I'm curious...

- Erik

The initial 'ideal' curve was quesstimated from static advance settings......

i.e., no springs, so curve was flat, and same throughout rpm range.

I had the timing at 2.5 deg, 5,7.5.....,30 degrees and figured out when it pinged... Got up to 17.5 deg before I found any pinging. If the ping then dissappeared at a higher rpm, I figured that advance was safe for the rpm........ Sort of a 'go' 'no go' method. I then plotted out the curve, and straightened it a bit as an initial curve to strive for.

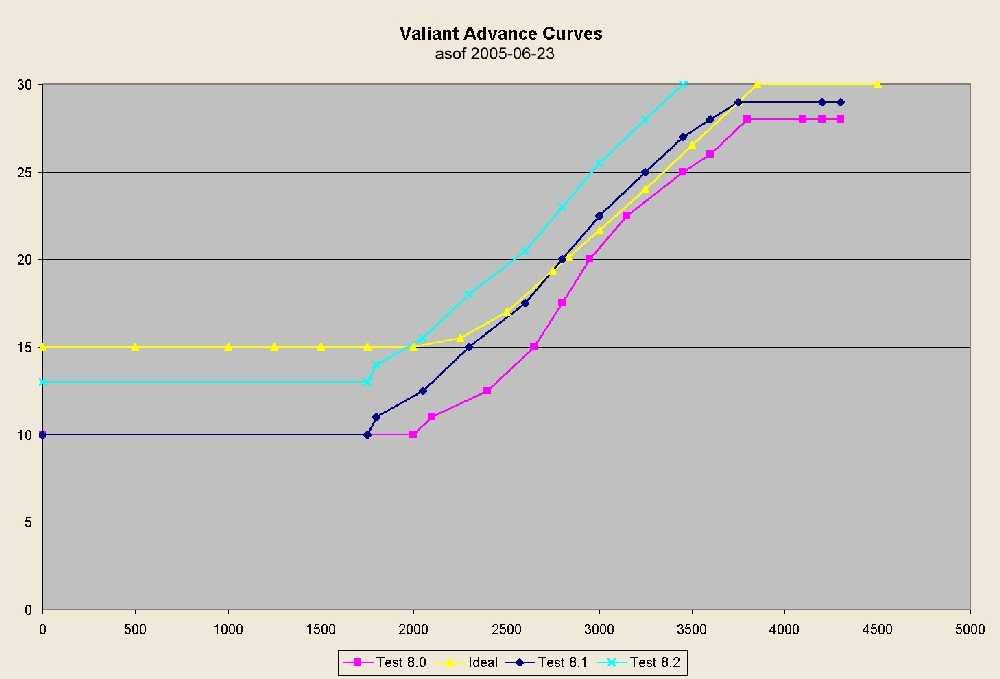

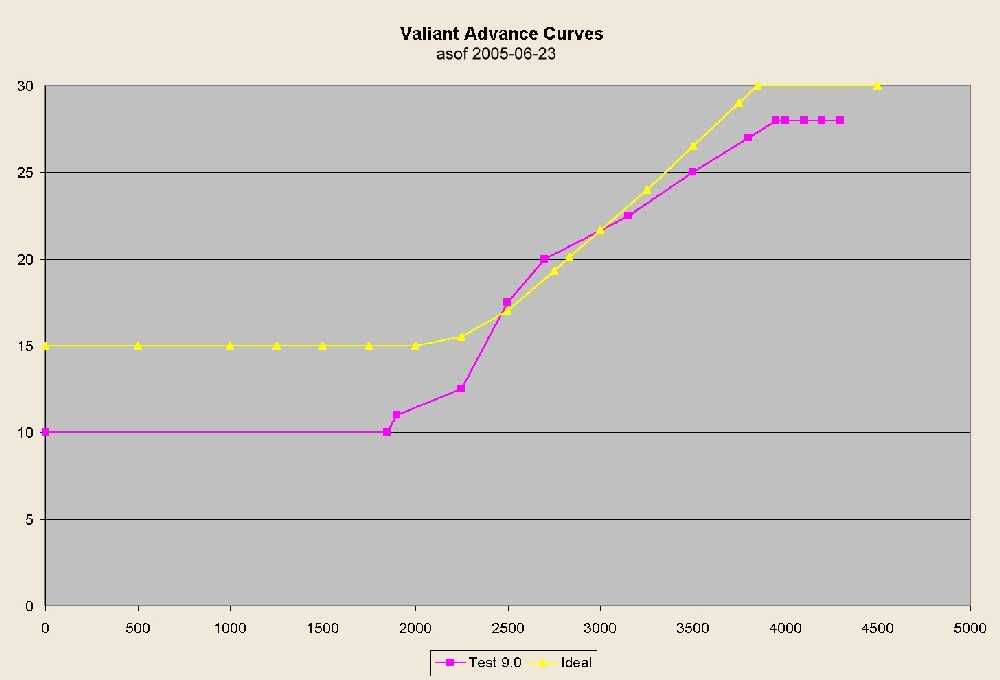

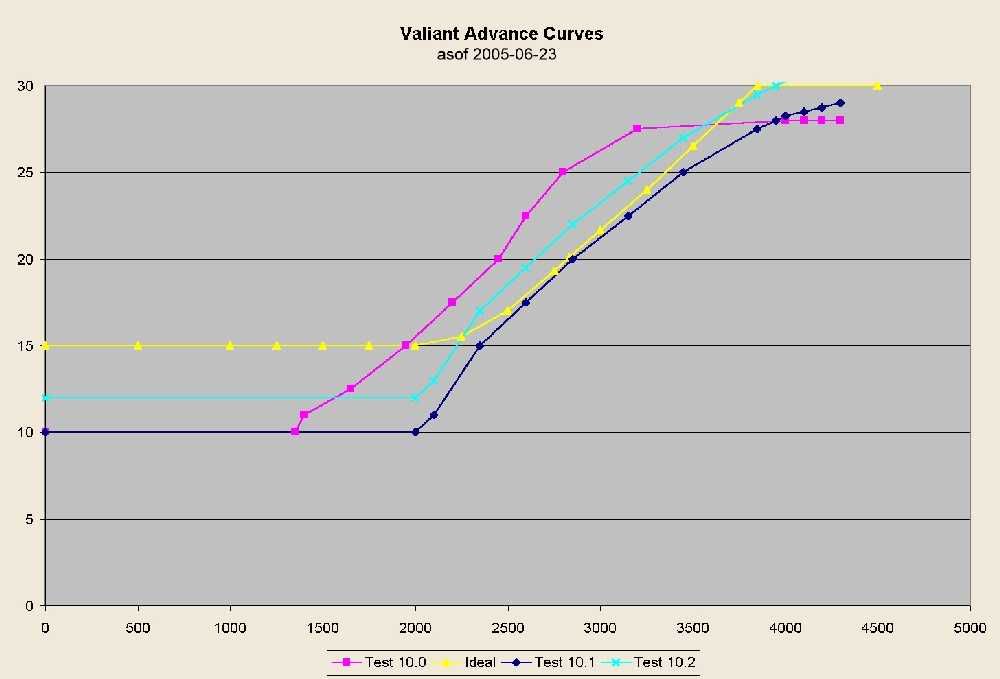

Then I'd put in some springs and see how close I could get to my 'ideal' curve. As a double-check I would see if the newly made curve pinged where I expected it to (usually at least 2 tests with different inital settings). Occasionally I found that it would ping when I didn't expect it to, or wouldn't ping when I expected it to. I would then adjust the 'ideal' curve to account for this.......

You can see that my initial ideal curve is a 2-step curve, but it evolved into a linear 1-step curve with further testing.

Since I was testing in 2.5 & 2 degree increments, I sort of figured that it was close enough to pick the last save spot as the ideal location (I read somewhere that the best spot is 2-3 degrees before the ping location). Without a brake dyno and the ability to adjust timing on the fly, that's probably the best I can do.......

I did read the Dr's book, and that's where I got the basis of my testing, I just figured using the static timing intially was a easier since I knew exactly what the timing is, and only have to observe RPM.

|