| Slant Six Forum https://www.slantsix.org/forum/ |

|

| acid dip and rust removal on hyper-pak bh block https://www.slantsix.org/forum/viewtopic.php?t=40838 |

Page 3 of 4 |

| Author: | 1969ronnie [ Fri Aug 27, 2010 10:01 am ] |

| Post subject: | block work |

|

|

| Author: | 1969ronnie [ Fri Aug 27, 2010 10:10 am ] |

| Post subject: | |

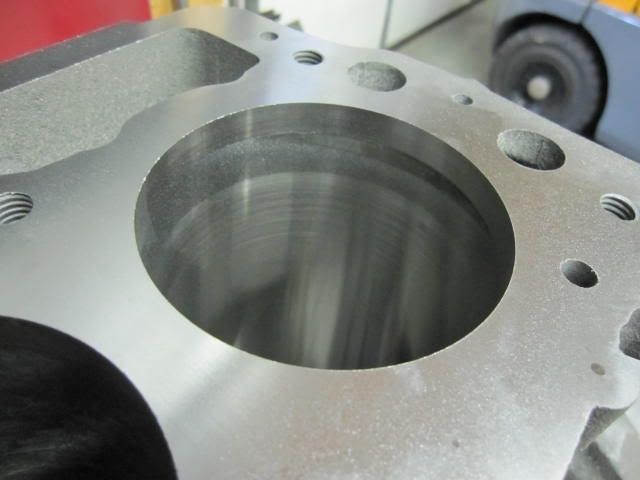

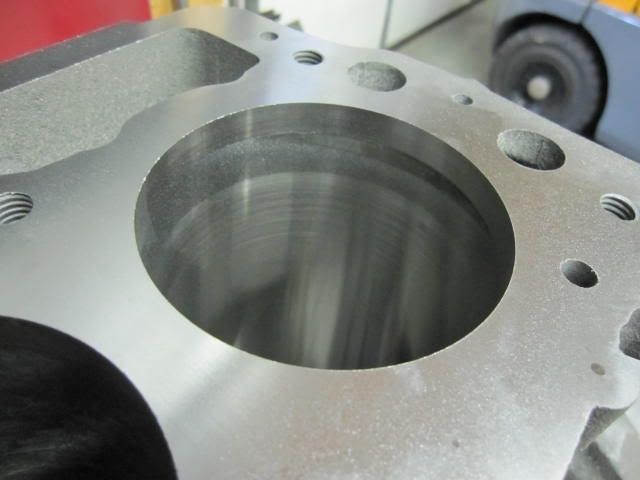

we took .003 off deck to start to see high and low spots. it took .005 to clean up perfectly. then .080 cut off deck . it's off to the boring machine next. trying to go .020 over but, there is .017-.018 ring ridge taper on cylinders 1 and 6. the pic shows .015 over , with .005 left for honing. looks like too much "eyebrow" for me to leave at .020 . what would you do? |

|

| Author: | carlherrnstein [ Fri Aug 27, 2010 1:21 pm ] |

| Post subject: | |

Try putting a straight edge ageist it and running a feeler gauge in there to guestimate how much needs to come out. good luck |

|

| Author: | RustyRamcharger [ Sat Aug 28, 2010 12:19 pm ] |

| Post subject: | |

0.005" is too much to remove by honing. Honing's purpose is to create the correct surface finish, not to size the bore. Typically you only remove ~0.001" with a hone. You'll have to rebore until you have a smooth cylinder, even if you need to sleeve the cylinder. Leaving the worn area could break the rings and/or piston lands, and will create a significant blowby leakage. Ken |

|

| Author: | Joshie225 [ Sat Aug 28, 2010 1:50 pm ] |

| Post subject: | |

Why only bore it +.020"? Do you already have pistons and rings in that size? If these blocks were rare and you planned on driving the vehicle 2 million miles I might only bore it .020", but if you're after HP and are using stock replacement pistons go +.060" and you'll still be able to go +.080" on the next rebuild. If you were buying custom pistons I'd bore it +.100". The Wiesco pistons are +.045 and +.085". |

|

| Author: | Dart270 [ Sat Aug 28, 2010 7:01 pm ] |

| Post subject: | |

I would bore at least 0.040". Most of these blocks can take 0.140" over, so 0.040" or 0.060" is nothing. Lou |

|

| Author: | 66aCUDA [ Sun Aug 29, 2010 7:09 am ] |

| Post subject: | |

Wiseco also has .105 over. ALL of there pistons use the new metric ring packs which have a lot less drag. You can also get all the fancy coating on them. Frank |

|

| Author: | 1969ronnie [ Wed Sep 01, 2010 5:14 am ] |

| Post subject: | honing |

|

|

| Author: | 1969ronnie [ Wed Sep 01, 2010 5:17 am ] |

| Post subject: | |

i just was going over docs notes about cylinder wall thickness. are you sure you can go .105 over? pictures of .020 over left a eyebrow, so going to .030. ronnie |

|

| Author: | Dart270 [ Wed Sep 01, 2010 5:25 am ] |

| Post subject: | |

I have a motor that is 0.192" over, running 15s in my truck and towing my racecar to the track. It was sonic checked by the guy who built it... 0.105" over is cake. Lou |

|

| Author: | 1969ronnie [ Thu Sep 16, 2010 5:48 pm ] |

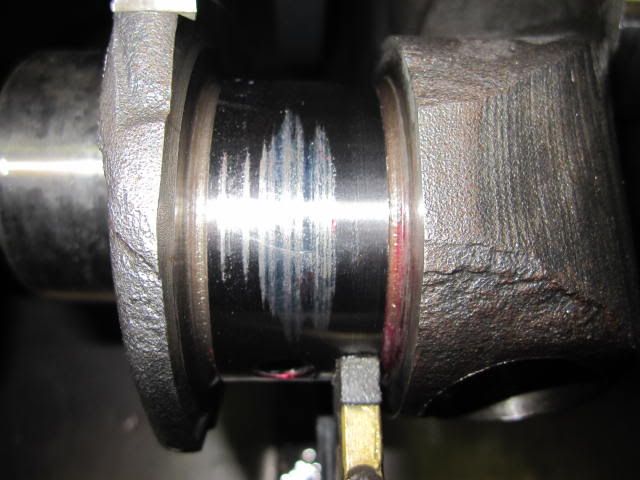

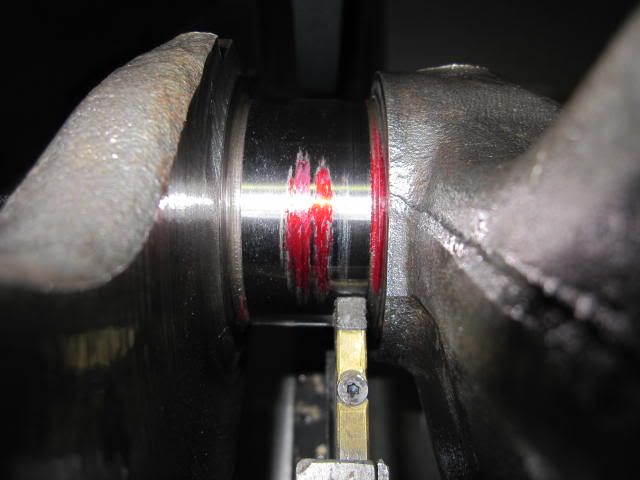

| Post subject: | crank grinding |

|

|

| Author: | 1969ronnie [ Thu Sep 16, 2010 5:49 pm ] |

| Post subject: | crank grinding |

|

|

| Author: | 1969ronnie [ Thu Sep 16, 2010 5:55 pm ] |

| Post subject: | |

power stroke side on crankshaft scratches/scores while undersize grinding. keep on grinding... |

|

| Author: | 1969ronnie [ Sat Sep 18, 2010 5:13 pm ] |

| Post subject: | flow bench |

|

|

| Page 3 of 4 | All times are UTC-08:00 |

| Powered by phpBB® Forum Software © phpBB Limited https://www.phpbb.com/ |

|