I believe you. I just haven't seen it. Usually 1/2"-1" is present on all the old junk I've played with.

CJ

| Slant Six Forum https://www.slantsix.org/forum/ |

|

| engine vacuum https://www.slantsix.org/forum/viewtopic.php?t=50191 |

Page 3 of 4 |

| Author: | kielbasa [ Sat Oct 27, 2012 10:45 am ] |

| Post subject: | |

Shouls i be getting 12" through tje distirbutor port? I thought it should be 0 at idle then picks up as you go |

|

| Author: | ceej [ Sat Oct 27, 2012 11:32 am ] |

| Post subject: | |

Your not going to see zero. There will always be something present. It depends on how far open the butterfly needs to be to maintain idle speed. 10° is a good place to start with timing. If you have basically stock compression, don't be afraid to bump it up to 12° base. Check timing all in with the vacuum can disconnected. It should be finished before 3500 rpm even with stock springs. Often, you will be able to tune that curve for better results based on vehicle weight, and what your trying to do. More compression, less mechanical advance. Once you get the timing bumped up a bit, you should be able to back off the curb idle and the signal should be lower at the ported vacuum connector. It still won't be zero. CJ |

|

| Author: | Reed [ Sat Oct 27, 2012 12:21 pm ] |

| Post subject: | |

I often see zero at the distributor advance port on the carb. I run mostly stock motors with stock carbs, but more often than not there is no vacuum at the dist port on the carb at idle. I think once I had a carb that showed something like three inches of vacuum, but most show zero. |

|

| Author: | ceej [ Sat Oct 27, 2012 12:39 pm ] |

| Post subject: | |

I believe you. I just haven't seen it. Usually 1/2"-1" is present on all the old junk I've played with. CJ |

|

| Author: | patrickhenryhague [ Sat Oct 27, 2012 1:29 pm ] |

| Post subject: | vacum and cams |

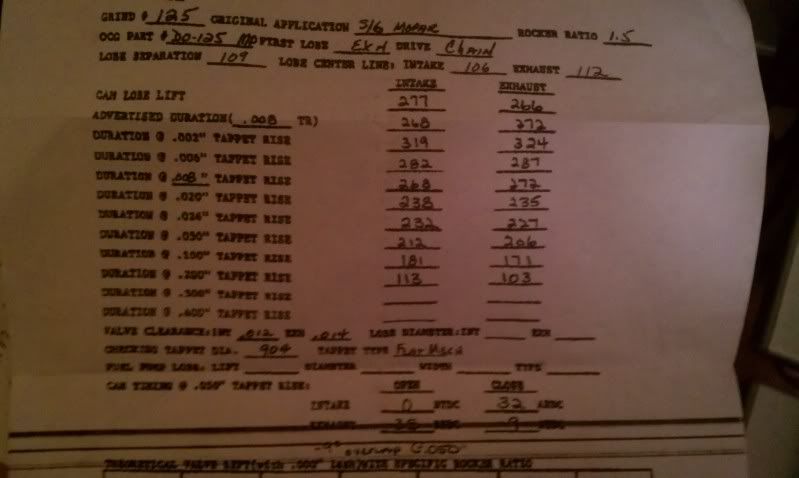

Just for an FYI and a request : Later madel slant 6s had Hyd. lifters early ones were solids. I am running a cam .435 lift, 252/o advertised duration, headers, 4bbl. and other stuff. It pulls 17 inches at idle at 790 rpms. advance 17 degrees a stock engine should pull 18 to 20. Taking vacum off of the #6 runner will work, like it was said it will be a little unsteady. On few slants intake manifolds there was a plugged vacum hole directly below the carb on the drivers side above the exhaust manifold. Tuning with a Vacum gauge, Timing light and a Tach. dwell meter really works just be careful not to dial in to much advance. Now for my request, just what are the specs. on an Oregon #125 cam and it is a re-grind, i'm curious that's all. In my opinion I've never personally cared for re-grinds I just don't like a smaller base circle thats all, one reason is for these engines to preform well on the streets they like lots of lift and long exhaust. I know that Direct Connections lists a 244/o duration with 436 lift that should be a great one but I've tried sevral time's to buy one and there never available hence I've got what I've got. |

|

| Author: | kielbasa [ Sat Oct 27, 2012 2:03 pm ] |

| Post subject: | |

Cam card for 125

|

|

| Author: | Aggressive Ted [ Sat Oct 27, 2012 2:40 pm ] |

| Post subject: | Vacuum pull off |

kielbasa, Check vacuum as Reed suggested. I have run my vacuum gauge "T" from the choke pull off for many, many years. Click on the red link below my name to view pictures of the "T" to the vacuum gauge. This is the only way you will find a true vacuum reading. The way you have done it will not be accurate. Give it a try and let us know what numbers you see. My carb always shows zero on the distributor port at 750 rpm idle. Just above that it starts to showing vacuum. |

|

| Author: | kielbasa [ Sat Oct 27, 2012 2:46 pm ] |

| Post subject: | |

I cannot. I've mentioned a few times in the thread its an early piston style pull off. No vacuum pod. I wish i could do it as easy as that. The #6 runner has a plug red lictited in... never thought I'd need it out. I tried removing and wrench started to strip the hex hole. I don't have my torch or heat gun handy its all in storage from the move. |

|

| Author: | Reed [ Sat Oct 27, 2012 3:39 pm ] |

| Post subject: | |

Fashion a spacer out of aluminum or wood and mount it between your carb and your intake. Before mounting the spacer, drill a hole in the side of the spacer all the way through to the throat of the bore. Install a small metal pipe into the hole you drilled and seal it in there. Now get your vacuum reading from the nipple of the pipe in the spacer you just installed. |

|

| Author: | ceej [ Sat Oct 27, 2012 5:56 pm ] |

| Post subject: | |

The OCG basic specs are in the Engine FAQ. OCG Mechanical OCG Hydraulic CJ |

|

| Author: | Aggressive Ted [ Sat Oct 27, 2012 7:30 pm ] |

| Post subject: | |

Quote: Fashion a spacer out of aluminum or wood and mount it between your carb and your intake. Before mounting the spacer, drill a hole in the side of the spacer all the way through to the throat of the bore. Install a small metal pipe into the hole you drilled and seal it in there. Now get your vacuum reading from the nipple of the pipe in the spacer you just installed.

Follow this advice. You can also use Bakelite material for a spacer which would help reduce heat soak, however aluminum might be easier to procure. Drill and tap a hole for a brass vacuum fitting.

|

|

| Author: | Reed [ Sat Oct 27, 2012 9:00 pm ] |

| Post subject: | |

Quote: Quote: Fashion a spacer out of aluminum or wood and mount it between your carb and your intake. Before mounting the spacer, drill a hole in the side of the spacer all the way through to the throat of the bore. Install a small metal pipe into the hole you drilled and seal it in there. Now get your vacuum reading from the nipple of the pipe in the spacer you just installed.

Follow this advice. You can also use Bakelite material for a spacer which would help reduce heat soak, however aluminum might be easier to procure. Drill and tap a hole for a brass vacuum fitting. |

|

| Author: | kielbasa [ Sat Oct 27, 2012 10:34 pm ] |

| Post subject: | |

I grabbed my torch and got the plug out of #6 runner. Noticed i was at about 14" of vacuum at 800rpm. So i tore into valve cover and loosened valves 2thou and saw it bumped up to 16"ish. Did another 2thou and got to 18". I left it at that as motor is noticably louder but obviously running better. Tightened everything up, set idle to 725/750rpm at 18" of vacuum. 10Degrees according to the timing tab, at 12/13 degrees according to my timing light. Its a brand new craftsman with a dial. Not sure which one to believe... lol Oh ya now I'm at less then 1" at the dist. Port. Now i have full advance and is very noticable while driving. Idle mixture screw is more responsive. Motor is smoother warm... gotta wait till morning to set choke and see how it goes from there. Things seem to be looking better thanks for all the help from everybody. I may try to bump timing to 15 but i need to pull dist. Since bracket is maxed out... such a retarded design on the dist. Bracket.... |

|

| Author: | kielbasa [ Sat Oct 27, 2012 10:36 pm ] |

| Post subject: | |

For anyones future reference OCG #125 seems to really like .016 intake / .018 exhaust. |

|

| Author: | Aggressive Ted [ Sun Oct 28, 2012 10:22 am ] |

| Post subject: | |

Glad you finally had success in tuning your engine. How long have you been running this cam? |

|

| Page 3 of 4 | All times are UTC-08:00 |

| Powered by phpBB® Forum Software © phpBB Limited https://www.phpbb.com/ |

|