Quote:

Key technique for avoiding leaks with a 2-half-circles neoprene rear main seal: offset the seams of the seal halves so they don't line up with the halves of the rear main bearing housing. The housing part line is horizontal, 9:00 to 3:00, so install the seal halves with their ends at about 10:00 and 4:00. A small dab of good quality RTV at each of the seal half ends, too.

As Doctor Dodge and yourself and various others have mentioned this is the best method can you explain why ?Is it if you install as per the Felpro instructions the joins would be in line with the block and cap creating a possible leak point even if you use RTV as suggested ?

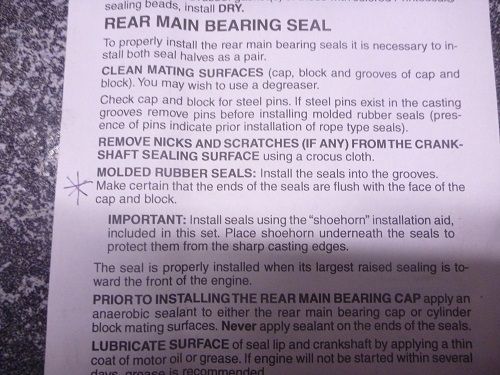

I am about to put my slant back together and have a Felpro gasket kit with the 2 piece rear main seal which I haven't used before.

When the seals are offset in the grooves will they move enough to butt up to each other ?

Or are they tight in the grooves and you have to align them spot on ?