Rick, I have a Jeffrey head I will loan you if you want it. No, it's not for sale.

| Slant Six Forum https://www.slantsix.org/forum/ |

|

| Covalt - "Project 65 Valiant" https://www.slantsix.org/forum/viewtopic.php?t=35632 |

Page 38 of 125 |

| Author: | Rick Covalt [ Thu Jan 17, 2013 12:28 pm ] |

| Post subject: | |

Hey Mark, Great to see you around here a bit! Quote: he goofed and built a head that got me a 11.42 na and 10.57 on the spray.

Yes, I am saving my $$$ to get a head from Mike. That will probably be a Jan 2013 project. I will be happy to do a head comparison on my car without any other changes. No, scratch that! i will need a cam change to take real advantage of the head!Rick |

|

| Author: | slantzilla [ Thu Jan 17, 2013 1:05 pm ] |

| Post subject: | |

Rick, I have a Jeffrey head I will loan you if you want it. No, it's not for sale. |

|

| Author: | Greg Ondayko [ Thu Jan 17, 2013 2:00 pm ] |

| Post subject: | |

Quote:

Yes, I am saving my $$$ to get a head from Mike. That will probably be a Jan 2013 project.

Rick WATCHU TALKIN 'BOUT WILLIS? IT IS JANUARY 2013. Get a Jeffery Head on there!... Borrow Big D's Just dont buy it, cause it's not for sale.. I cant blame the guy. |

|

| Author: | Rick Covalt [ Thu Jan 17, 2013 3:42 pm ] |

| Post subject: | |

Quote: Rick, I have a Jeffrey head I will loan you if you want it.

That is quite the offer Dennis. I really do appreciate it, but I'd be afraid something would happen to it. And you know I just would not want to take it off once it was on! I'll just keep moving ahead with my head as planned. But thanks anyway!Greg, I can't even remember my name sometimes! I'm thinking that the 65's came out in 1964, so 2014 would be the 50th anniversary for my car. That would be a good year to run a 12.99 ET. Rick |

|

| Author: | Greg Ondayko [ Thu Jan 17, 2013 7:29 pm ] |

| Post subject: | |

12.99 Fo' Sho. Greg |

|

| Author: | bmimken [ Tue Jan 22, 2013 6:50 am ] |

| Post subject: | |

Rick, glad to see you are making a lot of progress on the car! Can't wait to see you driving it down the track! Brian |

|

| Author: | Rick Covalt [ Sat Jan 26, 2013 11:39 am ] |

| Post subject: | |

Thanks Brian, I am going full steam ahead!!! I hope you have made some progress on tuning yours too! I got the Block / crank /rods back from the machine shop last evening. The first thing I did was set the head on the block and scribe marks around the bores to see how the head lined up.(If I did not do this right away, I know I would have forgotten) It needs to be shifted forward and towards the Intake side. I ordered offset dowels to do the job. I set my heater up under the block and after about a half hour it was nice and toasty and ready for a coat of paint. Installed the stand pipes in the lifter galley also. Now I'll go back to finishing up the exhaust ports on the head. Once the head is finished, I'll install the Cam and crank and check the clearances. One piston will be installed and get the deck height and then I can get the head cut to get me to @ 10.6 CR Parts list + price Complete 68-70 engine------------------$35 E-Bay Reconditioned 198 rods - ---------------$90 PAW years ago New 2.8L chevy pistons / Rings -------$35 E-Bay Reground Cam .513/506 / 290 -------$87 Oregon Cams Modified oil pump and hardened gear--$75 Doc New Lifters -------------------------------$24 E-Bay New Chromoloy Push Rods-------------$46 E-Bay Engine Builder Valves -------------------$87 E-Bay New Valve Springs ----------------------- $46 E-Bay Cylinder head work -----------------------$200 Machine shop Sonic check block ------------------------$ Free JP Billet timing set -----------------------$79 E-Bay Clevite Rod Bearings---------------------$19 E-Bay Clevite Mains -----------------------------$ 38 E-Bay Cam Bearings -----------------------------$ 22 Rock Auto Felpro Gasket set -------------------------$54 Rock Auto Windage Tray & Scraper -----------------$ 235 Mike Jeffrey ARP Rod Bolts ---------------------------$ 57 E-Bay Machine shop work -------------------- $630 Boring, decking, cooking, cam bearing, resize rods and install pistons, grind crank .030/.030 If my math is right I'm at $1860 . The only machining left is the final cut on the head which is @ $90. So my final total on this engine should be right around $1950 which should put me solidly into the 13's More to come, Rick |

|

| Author: | 1974duster kev [ Mon Jan 28, 2013 9:24 pm ] |

| Post subject: | |

Good stuff Rick! Kev |

|

| Author: | Rick Covalt [ Sat Feb 02, 2013 11:41 am ] |

| Post subject: | |

I have been out of commission for about a week with my back again. Not even sure how I hurt it! But I avoided the garage until this morning, when I had Micah come to the garage and help me set the crank in and check my clearances, and then I stuck in one piston to check my deck height. I was thinking I would be about .010 - .015 in the hole and it turned out to be .023. So once I get done in the chambers I can cut the head to get me to 10.6 -10.9 CR. Mike Jeffrey called and is sending my tray and scraper next week, and DI is sending the new distributor for this engine also. So I am making progress. Kind of getting anxious!! Rick |

|

| Author: | Rick Covalt [ Mon Feb 11, 2013 6:40 pm ] |

| Post subject: | |

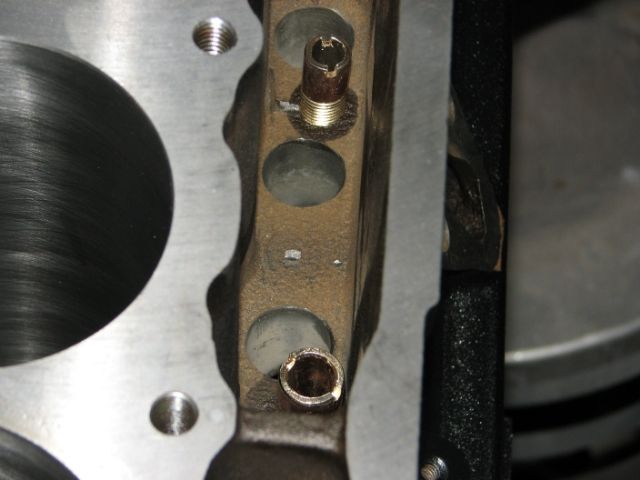

Here is a couple pictures (Boy I hate the new Photobucket)  This is a little blurry because it is hard to get a flash picture looking down the cylinder. You can see the purple dye is much wider to the top and left. The head was shifted about .025 using offset cam bushings.  The stand pipes I made were just about 1" length, with a notch cut in the top. Tool I made to tighten them up is on the right. there isn't much room down in the lifter galley to get a tool.  Installed stand pipes.  Again you can see the scribe mark on the head and how it was shifted. All my porting is done and I checked the chamber volume at 57CC. I think I will have cut to about 55CC and that should put me right at 10.9 to 1 CR Am I remembering correct that .006 is approximately 1CC ? Thanks Rick |

|

| Author: | Rob Simmons [ Wed Feb 13, 2013 7:51 am ] |

| Post subject: | |

Purdy! |

|

| Author: | Rick Covalt [ Mon Feb 18, 2013 5:03 pm ] |

| Post subject: | |

Pulled the head back off and pulled out my 2 valves. Re-mounted the head and put the piston at TDC. I took an old valve and cut the head off and put a point on it. Dropped it down number one Intake and Exhaust guide and made a punch mark in the top of the piston. This mark is for the machine shop to know where the valve centerline is. I will drop the pistons off and have a .100 notch cut into them. That will give me enough clearance to install the cam that Mike and I talked about on the phone next year or whenever I get ready. Measured my crank gear/cam gear misalignment at .095. Lou will cut the back side down on his lathe for me next weekend. I had hoped to have the short block all assembled this week, but I'd rather try and do it right and get it done a couple weeks late! Rick Timing gear alignment thread is here http://slantsix.org/forum/viewtopic.php ... 8&start=15 |

|

| Author: | Rick Covalt [ Mon Feb 25, 2013 3:57 pm ] |

| Post subject: | |

Had a great time at the banquet over the weekend and returned with my lower timing gear newly machined with .060 off the rear face. I installed it and it looks much better. Also needed to notch the pistons and the machine shop that was going to cut my pistons forgot that they were already on the rods.He needs them off, and then you risk breaking a piston. So I was going to use his tool to cut the notches while they were in the block. But he had no cutters even close to what I needed. So I just made my own. With some big block valves and some adhesive backed 80 grit long board sand paper. I dropped the 2 valves in the head and got some 3/8" collars with a allen head lock screw in them to adjust my depth of cut. I took it slow and it still takes less than 2 minutes to make a cut .100 depth. I need to go over them a little and smooth them some more and there is a small ridge at the bottom of the cut that I need to work on with the Dremel, but all in all I think they will be just fine. Total cost for my tools was less than $10. (I had the valves) Rick

|

|

| Author: | terrylittlejohn [ Mon Feb 25, 2013 6:45 pm ] |

| Post subject: | |

nice job and great idea on cutting reliefs |

|

| Author: | Dart270 [ Mon Feb 25, 2013 6:53 pm ] |

| Post subject: | |

Very nice, and way prettier than what I did freehand with a die grinder... Lou |

|

| Page 38 of 125 | All times are UTC-08:00 |

| Powered by phpBB® Forum Software © phpBB Limited https://www.phpbb.com/ |

|