The components in question do not see the same temperatures or heat transfer, nor do they have consistent temperatures throughout themselves. It would take quite a computer simulation to accurately predict dimensional changes in the various run cycles.

Chrysler engineers did a good job of allowing for differential expansion on the longer parts. That's why installing the manifolds should be done correctly. See Doug and Dan's article:

http://www.slantsix.org/articles/manifo ... unting.htm

Intakes are cooled in the plenum and ports by the air/fuel mixture passing through, and are heated by the exhaust gases hitting the base (stock slant manifolds and Offys, IIRC), by radiation from the exhaust manifolds, and by some conduction through the gaskets.

Exhaust manifolds are the hottest, of course, with convection from the exhaust gases.

Heads see combustion heat in the chamber and exhaust ports, cooling from the air/fuel mix, heat transfer to the coolant and oil ... A pretty complicated thermodynamic situation.

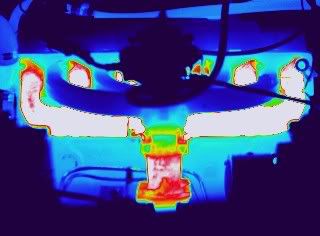

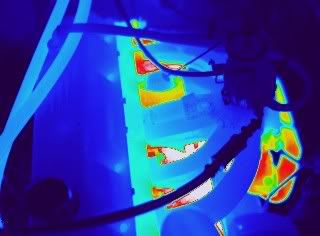

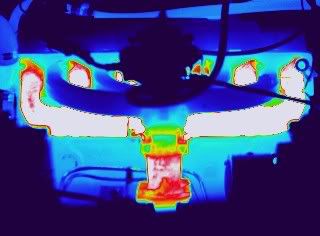

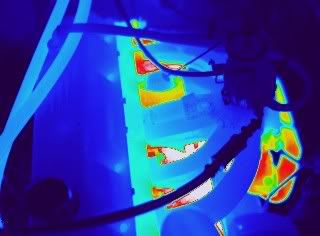

Thermographs: White is hottest, black is coldest

|