A CNC laser machine works pretty good!

For the "do it yourselfer"... a tool called a "nibbler" works pretty good for trimming sheet metal.

The sanding roll will work, use wax on it to keep it from clogging.

DD

| Slant Six Forum https://www.slantsix.org/forum/ |

|

| Need input on shaping aluminum. https://www.slantsix.org/forum/viewtopic.php?t=24549 |

Page 1 of 2 |

| Author: | DionR [ Mon Aug 20, 2007 12:55 pm ] |

| Post subject: | Need input on shaping aluminum. |

| Author: | Doc [ Mon Aug 20, 2007 1:14 pm ] |

| Post subject: | |

A CNC laser machine works pretty good! For the "do it yourselfer"... a tool called a "nibbler" works pretty good for trimming sheet metal. The sanding roll will work, use wax on it to keep it from clogging. DD |

|

| Author: | DionR [ Mon Aug 20, 2007 1:43 pm ] |

| Post subject: | |

Quote: A CNC laser machine works pretty good!

Or just buying the part completed instead of "rolling your own".Quote: For the "do it yourselfer"... a tool called a "nibbler" works pretty good for trimming sheet metal.

Remember, this is almost an inch thick. Quote:

The sanding roll will work, use wax on it to keep it from clogging.

Just smear some wax on it and go? |

|

| Author: | sandy in BC [ Mon Aug 20, 2007 2:18 pm ] |

| Post subject: | |

Band saw or Jigsaw with aggressive blade. I have only a drill press and hand tools so I end uo doing a lot of hand work. (Yes!....I handfiled my 7.25 spring plates to fit the bigger Ubolts for my 8.8 swap....I like chainsaw files) I hand filed my bellhousing to do my 5 speed swap....took almost 5 hours. You can never make a big mistake handfiling....you almost always get a good "press fit". I like a good jig saw for what you are doing....my local machine shop has really good blades for almost any metal. Sometimes a hand hack saw is faster and easier than wrestly a bouncing jig saw..,,, |

|

| Author: | Mike_64_Valiant [ Mon Aug 20, 2007 4:25 pm ] |

| Post subject: | |

I am not sure how much material you are looking at removing but because its so thick the best bet would be to use a good band saw very slow and a band blade with about 30 to 32 teeth per inch. Or a pneumatic die grinder and use a cutting disk and clean the edges with sanding disks. Now that involves a good air compressor and the die grinder not everybody has. So one other option could be chain drilling. You do this by laying out the cut line and then using a good kobalt drill bit and slow speed just stay outside of the cut line and drill one hole right next to the other and then sand or file the remaining material. I hope this helps. Michael |

|

| Author: | jwh723 [ Mon Aug 20, 2007 4:27 pm ] |

| Post subject: | |

I have used a router with a good carbide bit to shape aluminum. Use lots of oil and good eye protection, the chips do fly! If you go slow you can get a nice finish, to fast and the bit will chatter (jump). JWH723 |

|

| Author: | sick6 [ Tue Aug 21, 2007 4:13 am ] |

| Post subject: | |

Quote: A CNC laser machine works pretty good!

a cnc laser (C02 anyway) would probably warp it and change its hardness value. a regular CNC cutter (say with a 1/4 to 1/2 bit) would work great, I run one of these now. 15000 rpm at 50 ipm with an air assist works on the cheap ass cutters they buy here (single flute not really meant for milling)........a waterjet would be ideal, no heat strength loss and a resonable finished edge depending on the speed you use. (.040 nozzle, .012 orifice, 80 alluvial garnet). Super pricey though. Too bad your way out there, you could just drop it by here and I could do it on the weekend. |

|

| Author: | DionR [ Tue Aug 21, 2007 11:36 am ] |

| Post subject: | |

Quote: I have used a router with a good carbide bit to shape aluminum. Use lots of oil and good eye protection, the chips do fly! If you go slow you can get a nice finish, to fast and the bit will chatter (jump). JWH723

What kind of bit? Can you give me specifics?Could I chuck it in a drill press and run it like a router table? |

|

| Author: | DionR [ Tue Aug 21, 2007 11:38 am ] |

| Post subject: | |

Quote: Too bad your way out there, you could just drop it by here and I could do it on the weekend.

Story of my life, "too far...too much...not enough..." Thanks for the offer! |

|

| Author: | sick6 [ Tue Aug 21, 2007 12:15 pm ] |

| Post subject: | |

Quote: Quote: I have used a router with a good carbide bit to shape aluminum. Use lots of oil and good eye protection, the chips do fly! If you go slow you can get a nice finish, to fast and the bit will chatter (jump). JWH723

What kind of bit? Can you give me specifics?Could I chuck it in a drill press and run it like a router table? Ahhhh! no! don't even try to do that! I don't think the RPM would be high enough and trying to hold onto the part would be a nightmare. you can make your own router table pretty easily. take a regular router (such as for shaping wood, like you would use to put a chamfer on a cabinet door, those "two handed" models) and attach the base to a flat piece of plywood, cut a hole for the bit to go through. flip it over, put some legs on it and you got yourself a router table. of course, this ONLY works if you find a router that can handle the right RPM for the bit and you have some sort of fence to guide your workpiece on, but it will be much more stable than a press. Enco is a good source for carbide bits. stay away from "high speed steel" and go with the carbide. specific rpm/speed numbers depend on the diameter of the bit and how thick the piece is your cutting. |

|

| Author: | ceej [ Tue Aug 21, 2007 12:33 pm ] |

| Post subject: | |

What kind of adapter are you making? If it's so unique that you have to make one, find somebody with a milling machine. Using a router may be possible, but isn't going to be safe in any configuration I can think of. The bits aren't designed for that sort of thing, and your spindle speed is unlikely to be appropriate. Even the light milling machines out of China are going to be safer for that sort of thing. There are conversions and vises available to use a drill press as a mill. Keep in mind that few drill presses have the right speeds for working with end mills. Close but not quite. Too slow and too fast result in poor finish and/or damage. The vises aren't terribly accurate, and too much load can cause deflection of the entire setup. In addition, the spindles aren't really designed to carry side loading. Look at the diameter of a milling machine spindle, then look at a drill press. Big difference. Be careful out there! Grizzly Industrial (toy) G9729 Mill/Drill/Lathe 5" Milling Vice For heavy, complex setups I use the Bridgeport's and other Machine tools at work. CJ Only six hours away... Halsey Oregon |

|

| Author: | DionR [ Tue Aug 21, 2007 1:03 pm ] |

| Post subject: | |

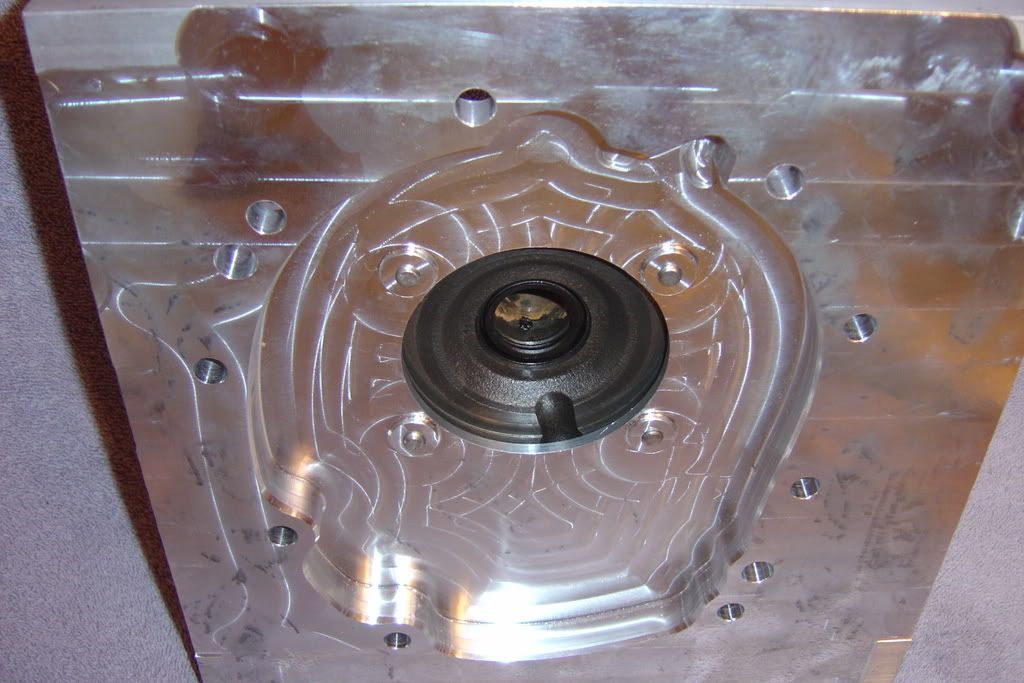

Here is what I am working on I'm not trying to finish the outside shape to any precision measurements, I just want to make it more closely follow the shape of the BH and trans, rather than the "triscuit" shaped adapter I started with. |

|

| Author: | DionR [ Tue Aug 21, 2007 1:08 pm ] |

| Post subject: | |

Quote: CJ

So close, yet so far away...Only six hours away... Halsey Oregon |

|

| Author: | jwh723 [ Tue Aug 21, 2007 1:09 pm ] |

| Post subject: | |

The carbide cutter I used was for high pressure laminate, with a ball bearing on the bottom. They come in all different profiles. I used a 45 deg. one to cut a bevel on the back of a old slotted rim to clear the brake drum weights on my 70 Swinger before I went to disks, just took small cuts, cut like butter! A drill press will not be fast enough. I have seen guys use router tables too. JWH723 |

|

| Author: | sick6 [ Wed Aug 22, 2007 7:45 am ] |

| Post subject: | |

say dion, this might be easier if you could find out what shipping that thing to area code 55434 might be, then I could do it. I'd have to check with the boss to see the price yet, but if you check the shipping and ask around at local shops what the cost might be, we can figure out what is the best deal for you. Because right now it looks like you have all the ability you need, but you just don't have access to the right equipment. |

|

| Page 1 of 2 | All times are UTC-08:00 |

| Powered by phpBB® Forum Software © phpBB Limited https://www.phpbb.com/ |

|