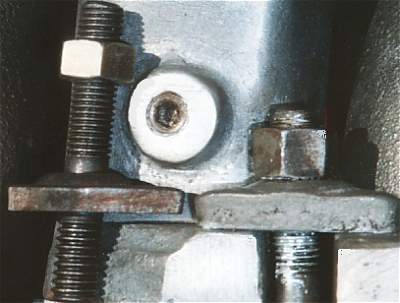

Followed the procedure and bolted the intake and exhaust loosely together until the assembly was torqued to the head.

The intake is original and exhaust is new.

There was an extremely slight problem on one end with the surface alignment gauging with a straightedge. So there was some warping but it seemed insignificant.

Taking it out today, if it will perfectly align with the three bolts removed I might be able to fix it by enlarging the 3 mounting holes in the intake to allow a little more wiggle room. But then again it is such a pain I might as well wait for the $$$$ gaskets so I don't have to tear it down 3 times.