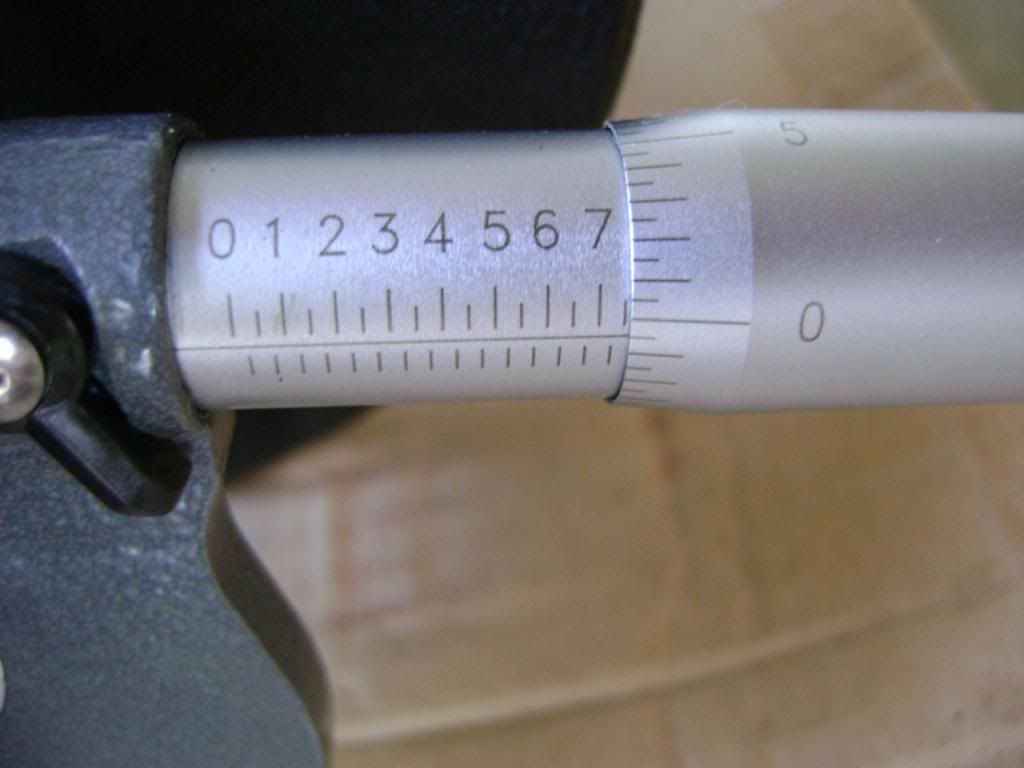

I'm busily micing my crank for my 225 rebuild. Picked up a set of Harbor Freight (I know..) micrometers. They only measure down to .001", but was hoping they'd work.

Here's photos of my readouts. Even if I'm not reading to the .0001" there seems to be something wrong because I'm reading that I'm OVER spec on my readouts. FSM states main bearings spec is 2.7495-2.7505. Don't understand how that could be, unless I'm totally reading the micrometer wrong. I made sure to calibrate the micrometer to 0, then to get the anchor and spindle positioned correctly on the main journals, taking into account I probably didn't want to measure in the middle because there's the oil groove there, so possibly less wear, so I offset the pins from the journal center to get an accurate wear reading.

Here's the photos, what do you all think? With the exception of MB #4, they all seem to be around the same readout, which makes me think I'm reading the mic wrong....:

General Setup

Micrometer I'm using

MAIN 1 HORIZONTAL READOUT

MAIN 1 VERTICAL READOUT

MAIN 2 HORIZONTAL READOUT

MAIN 2 VERTICAL READOUT

MAIN 3 HORIZONTAL READOUT

MAIN 3 VERTICAL READOUT

MAIN 4 HORIZONTAL READOUT

MAIN 4 VERTICAL READOUT